Growing atomic-scale materials

Scientists from New York University (NYU) have developed a method for growing an atomic-scale electronic material at what is said to be the highest quality ever reported.

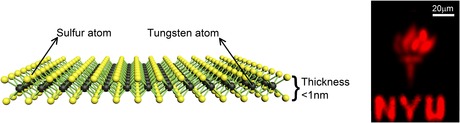

The promise of two-dimensional electronic materials has tantalised researchers since the discovery of graphene more than a decade ago. Also called ‘monolayer’ materials, graphene and similar 2D materials are one atom in thickness, several hundred thousand times thinner than a sheet of paper.

These materials boast major advantages over silicon — namely unmatched flexibility, strength and conductivity — but developing practical applications for their use has been challenging. For example, graphene (a single layer of carbon) has been explored for transistors, but its lack of an energy band gap poses difficulties for semiconductor applications.

“You can’t turn off the graphene transistors,” said Davood Shahrjerdi, an assistant professor at the NYU Tandon School of Engineering.

Shahrjerdi and doctoral student Abdullah Alharbi chose to work with tungsten disulfide — a synthetic material with a wide range of electronic and optoelectronic applications and a sizeable energy band gap. When the number of atomic layers increases, the band gap becomes tuneable, and at monolayer thickness it can strongly absorb and emit light, making it suitable for applications in optoelectronics, sensing and flexible electronics.

Efforts to develop applications for monolayer materials are often plagued by imperfections in the material itself — impurities and structural disorders that can compromise the movement of charge carriers in the semiconductor (carrier mobility). Shahrjerdi and Alharbi managed to reduce these structural disorders in tungsten disulfide by omitting the growth promoters and using nitrogen as a carrier gas, rather than the more common choice of argon.

“We developed a custom reactor for growing this material using a routine technique called chemical vapour deposition,” said Shahrjerdi. “We made some subtle and yet critical changes to improve the design of the reactor and the growth process itself, and we were thrilled to discover that we could produce the highest quality monolayer tungsten disulfide reported in the literature.”

The researchers reported their results in the journal Applied Physics Letters. Shahrjerdi said of the technique, “It’s a critical step toward enabling the kind of research necessary for developing next-generation transistors, wearable electronics and even flexible biomedical devices.”

Electronex Expo returns to Sydney for 2024

Electronex — the Electronics Design and Assembly Expo will return to Sydney in 2024,...

Mouser opens customer service centre in Melbourne

Mouser Electronics has opened a customer service centre in Melbourne to support its customers...

Global semiconductor market to grow 17% in 2024

Following an 11% decline in revenue in 2023, Gartner analysts are predicting an uptick for...