Amplifying light with designer quantum dots

US scientists have successfully amplified light using electrically excited films of chemically synthesised semiconductor nanocrystals, known as quantum dots. The quantum dot films are integrated into devices much like light-emitting diodes (LEDs), but are in this case designed to sustain the high current densities required for achieving the optical-gain regime.

A key element of laser diodes — found in applications such as lasers pointers and barcode readers — is an optical-gain medium, which amplifies light instead of absorbing it. Now, thanks to Victor Klimov’s team at Los Alamos National Laboratory, optical gain with electrically excited quantum dots has become a reality.

“We have been working to develop new lasing media using chemically synthesised quantum dots, although it had been widely believed that quantum dot lasing with electrical stimulation is simply impossible,” said Klimov. “By using our specially designed dots, we can avoid energy losses created by Auger recombination.”

The Los Alamos nanotechnology team originally discovered the lasing effect in semiconductor nanocrystals in 2000. In proof-of-principle experiments reported in the journal Science, the quantum dots were stimulated with very short (femtosecond) laser pulses used to outcompete optical gain decay caused by the Auger process. Short optical gain lifetimes create an especially serious problem in the case of electrical pumping, which is an inherently slow process as electrons and holes are injected into the quantum dot one by one.

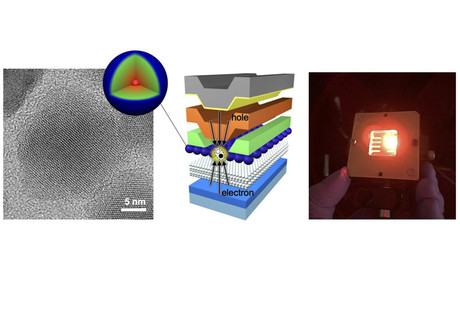

Seventeen years later, writing in the journal Nature Materials, the Los Alamos team described how their ‘designer’ quantum dots enable light amplification in a nanocrystal solid with direct-current electrical pumping. The key property of the novel quantum dots is a carefully engineered particle interior in which the material’s composition is continuously varied along a radial direction. This approach eliminates sharp steps in the atomic composition which would normally trigger Auger recombination.

As a result, the engineered quantum dots feature nearly complete suppression of the Auger effect’s heat loss. This allows for redirection of the energy released by the electrical current into the light-emission channel instead of wasteful heat.

Another important element of this work is a special ‘current-focusing’ device architecture which enables the high-current densities necessary for achieving optical gain. The researchers achieved this by tapering one of the charge-injection electrodes, limiting the size of the current-conducting area to less than 100 microns. Using this strategy, they were able to produce current concentration sufficient to reach the regime of light amplification without damaging either the dots or the injection layers.

These results demonstrate the feasibility of a new generation of highly flexible, electrically pumped lasers processable from solutions that can complement or even eventually displace existing laser diodes fabricated using more complex and costly vacuum-based epitaxial techniques. These prospective devices can enable a variety of applications, from RGB laser modules for displays and projectors to multiwavelength micro lasers for biological and chemical diagnostics.

Hidden semiconductor activity spotted by researchers

Researchers have discovered that the material that a semiconductor chip device is built on,...

3D reflectors help boost data rate in wireless communications

Cornell researchers have developed a semiconductor chip that will enable smaller devices to...

Scientists revolutionise wireless communication with 3D processors

Scientists have developed a method for using semiconductor technology to manufacture processors...