Growing 2D crystals for future electronics

Ever since the discovery of graphene, scientists have examined many other 2D materials, both those found in nature and concocted in the lab. But growing high-quality, crystalline 2D materials at scale has proven a significant challenge — until now.

Researchers at Pennsylvania State University recently published two papers providing the basis for growing wafer-scale 2D crystals for future electronic devices. The papers were co-authored by Professor Joan Redwing and Associate Professor Joshua Robinson, both members of the Penn State Two-Dimensional Crystal Consortium – Materials Innovation Platform, a National Science Foundation national user laboratory advancing the state of the art in the crystal growth of atomically thin 2D materials for next-generation electronics.

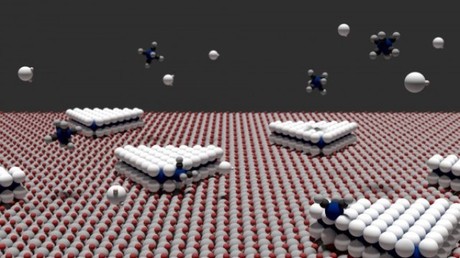

In work led by Professor Redwing, Penn State researchers developed a multistep process to make single-crystal, atomically thin films of tungsten diselenide across large-area sapphire substrates. Their research was published in the journal Nano Letters.

“Up until now, the majority of 2D devices have been fabricated using small flakes that are exfoliated off of bulk crystals,” Professor Redwing said. “To develop a device-ready technology, you have to be able to make devices on large-area substrates and they have to have good crystal quality.”

The process uses sapphire as the substrate because of its crystalline structure. This structure orients the film growth in a crystal pattern in a process called epitaxy. As small islands of the material form on the substrate and the substrate is heated, the islands spread out across the substrate in a uniform pattern forming a large-area film without gaps and with very few defects. The key advance was the use of gas source chemical vapour deposition to precisely control the island density and rate of spreading to achieve a single layer of the 2D material.

In a related paper, Associate Professor Robinson and his team provide the foundational understanding to enable device-ready synthetic 2D semiconductors based on these epitaxial large-area films in future industrial-scale electronics. Their work was published in ACS Nano.

“The primary significance of this work is we were able to achieve an understanding of the extrinsic factors that go into having a high-quality 2D material,” Associate Professor Robinson said. “What we found was that even when you grow oriented crystals on a surface, there are other factors that impact the ability to get high electron mobility or fast transistors.”

In particular, the researchers found that there is a strong interaction between the sapphire substrate and the monolayer film, with the substrate dominating the properties. To overcome these challenges, the team grew two or three layers, which improved the performance by factors of 20–100 times.

“This is the first real evidence of the effect of the substrate on the transport properties of 2D layers,” Associate Professor Robinson said.

Fully coupled annealing processor for enhanced problem solving

Researchers have designed a scalable, fully-coupled annealing processor with 4096 spins, and...

STMicroelectronics breaks 20 nm barrier for next-gen microcontrollers

STMicroelectronics has launched an advanced process based on 18 nm Fully Depleted Silicon On...

Chip opens door to AI computing at light speed

A team of engineers have developed a silicon-photonics chip that uses light waves, rather than...