Nanoalloys reduce the need for platinum in fuel cells

European researchers have shown that it is possible to significantly reduce the need for platinum in fuel cells through the development of a new type of nanocatalyst. Their technology could be the breakthrough the fuel cell car industry has been waiting for and is apparently suitable for mass production.

Even though there have been fuel cell cars for about 50 years, they have not yet made a commercial breakthrough. Part of the reason for this is that the catalysts in today’s fuel cells require large amounts of platinum, which is one of the world’s most expensive metals.

Previous research has shown that it is possible to mix platinum with other metals, such as yttrium, to reduce the amount of platinum in a fuel cell. Unfortunately, no-one has yet managed to create alloys with these metals in nanoparticle form in a manner that can be used for large-scale production. The major problem has been that yttrium oxidises instead of forming an alloy with the platinum.

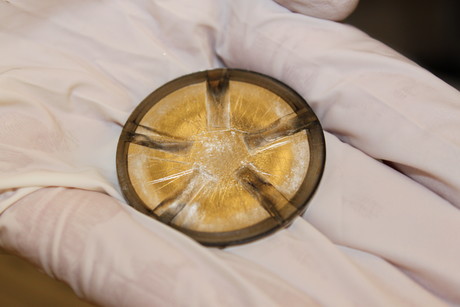

This problem has now been solved by a research team led by Sweden’s Chalmers University of Technology by combining the metals in a vacuum chamber using a technique called sputtering. The result of their research, published in the journal Advanced Materials, is a nanometre-thin film of a new alloy that enables mass-produced platinum and yttrium fuel cell catalysts.

“A nano solution is needed to mass-produce resource-efficient catalysts for fuel cells,” said Björn Wickman, a researcher at Chalmers University of Technology and corresponding author on the study. “With our method, only one-tenth as much platinum is needed for the most demanding reactions. This can reduce the amount of platinum required for a fuel cell by about 70%.”

If this level of efficiency is possible to achieve in a fuel cell, the amount of required platinum would be comparable to what is used in an ordinary car catalytic converter. “Hopefully,” said Wickman, “this will allow fuel cells to replace fossil fuels and also be a complement to battery-powered cars.”

To use the new material, today’s fuel cells need to change slightly, but doing so creates incredible opportunities. As explained by Chalmers researcher Niklas Lindahl, also a corresponding author on the study, “Fuel cells convert chemical energy into electrical energy using hydrogen and oxygen — with water as the only product. They have huge potential for sustainable energy solutions in transport, portable electronics and energy.”

Four-terminal tandem organic solar cell achieves 16.94% PCE

Researchers have fabricated a new four-terminal organic solar cell with a tandem configuration...

Scientists unveil novel material for magnesium batteries

Researchers have developed a cathode material for rechargeable magnesium batteries that could...

Researchers develop high-efficiency DC power converter

Researchers have developed a direct current voltage boost converter that could contribute to the...