'World's smallest sensor' will never need replacement batteries

They say good things come in small packages, and that’s a fair statement when it comes to the latest development from Fujitsu Laboratories. The company claims to have created the world’s smallest sensor — a device that supports low-power wide-area (LPWA) technology and will apparently never need replacement batteries.

As the spread of IoT systems gains momentum, expectations are rising for sensor devices that support LPWA technology, which can wirelessly transmit sensor information directly to the cloud. In order to create systems that employ this technology, there has been a demand for easy-to-install miniature devices powered by solar cells to achieve both convenience and low cost, thus dispensing with the need to replace batteries.

Fujitsu previously developed power control technology using miniature circuits that can transmit data over short distances wirelessly using Bluetooth Low Energy (BLE). This technology realises sensor devices that support BLE without the need to exchange batteries, providing power via solar cells and reliably activating a wireless circuit by monitoring and adjusting the balance between power generation and consumption.

Sensor devices using this previous technology, however, could not support LPWA, as the time required for transmission with LPWA is significantly longer than with BLE. LPWA transmits small amounts of data slowly in order to ensure signal quality over long distances. In effect, this means that a single transmission can require significant power usage of up to about 1500 times that of BLE.

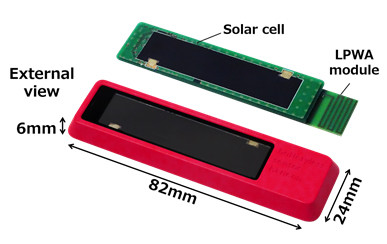

Now, Fujitsu has developed power control technology that ensures adequate transmission power while minimising circuit size. This has enabled the company to miniaturise the device to a size of 82 x 24 x 6 mm, while still supporting the LPWA and never requiring replacement batteries.

The power control technology can control the timing of LPWA signal transmissions in real time, based on temperature data collected from a temperature sensor. Signal transmissions are only carried out when the activation voltage, which varies with temperature, is maximised in order to prevent it from falling below the minimum operational voltage for the LPWA module. By using power efficiently in this way, it is possible to tolerate variation in power consumed by the wireless circuit or power generated by solar cells due to temperature. This eliminates the need for the excess energy storage elements that were previously necessary to respond to power fluctuations.

In order for the power control technology to operate reliably, the device must be able to continually and reliably activate the temperature sensor with a small amount of power. To resolve this challenge, Fujitsu has developed power monitoring technology that analyses voltage changes in the power source and judges whether or not sufficient power has been stored to operate the temperature sensor. This technology can prevent unnecessary shutdowns of the temperature sensor by using the minimum amount of power based on the temperature.

Testing the new technology, Fujitsu verified that temperature and humidity data could be transmitted via the miniature sensor once every 10 min over seven days directly to a Sigfox base station about 7 km away, in an environment with illumination of 4000 lux. The company also verified that the data could be visualised through the Fujitsu Cloud Service K5 IoT Platform, an IoT data utilisation platform service. This means that sensor data can easily be acquired in the cloud just by setting sensor devices — even in places where it is difficult to secure power or install power cables — thus enabling maintenance-free installation and management of IoT systems.

Fujitsu will continue to conduct field trials aimed at the real-world use of these sensor devices, incorporating their technology into the Fujitsu Cloud Service K5 IoT Platform and Fujitsu Frontech sensor solutions as connected devices. The company aims to achieve commercialisation in fiscal 2018.

Machine learning used to create fabric-based touch sensor

Integrated into clothing, the device can control mobile apps, enter passwords and play video games.

Wearable sensor measures real skin feel

A team of researchers has developed a wearable skin sensor that offers precise, objective and...

Handheld sensor enables rapid detection of multiple bacteria

Researchers have developed a handheld biosensor that can simultaneously detect multiple...