Turning soybeans into graphene

Graphene has long been lauded as something of a wonder material, with its thin composition and high conductivity meaning it is used in applications ranging from miniaturised electronics to biomedical devices. Now, scientists led by CSIRO have made the world’s strongest material more commercially viable with the help of the humble soybean.

Graphene is typically grown in a highly controlled environment with explosive compressed gases, requiring long hours of operation at high temperatures and extensive vacuum processing. This high cost of production has so far served as a major roadblock in the material’s commercialisation.

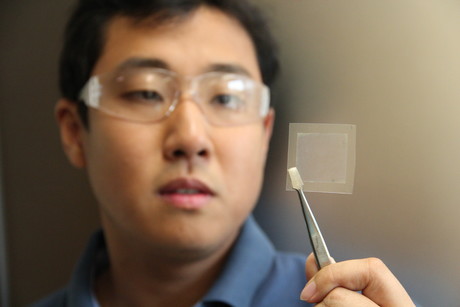

The CSIRO team have now developed ‘GraphAir’ technology, which eliminates the need for such a controlled environment. Writing in the journal Nature Communications, the scientists explained that GraphAir enables graphene film to be grown in ambient air with a natural precursor, making its production faster and simpler.

“This ambient-air process for graphene fabrication is fast, simple, safe, potentially scalable and integration-friendly,” said Dr Zhao Jun Han, a co-author on the study.

So where do the soybeans come in? Well, heat breaks down soybean oil into a range of carbon building units that are essential for the synthesis of graphene, which is itself a carbon material. The team additionally managed to transform other types of renewable and waste oils, such as those left over from barbecues or cooking, into graphene films.

“We can now recycle waste oils that would have otherwise been discarded and transform them into something useful,” said co-author Dr Dong Han Seo.

“Our unique technology is expected to reduce the cost of graphene production and improve the uptake in new applications,” added Dr Han.

Electronex Sydney a major success

More than 1000 trade visitors and delegates have attended the Electronics Design & Assembly...

Gartner: Global AI chips revenue to grow 33% in 2024

Gartner has forecast that the revenue from AI semiconductors globally will total $71 billion in...

Electronex Expo returns to Sydney for 2024

Electronex — the Electronics Design and Assembly Expo will return to Sydney in 2024,...