Elastic nanomembrane developed for skin electronics

Skin electronics require stretchable conductors that satisfy a range of characteristics, but it is challenging to achieve these simultaneously. Researchers at South Korea’s Institute for Basic Science (IBS) have now developed a method to fabricate a nanomembrane that satisfies all requirements, with their results published in the journal Science.

‘Skin electronics’ are thin, flexible electronics that could be mounted onto the skin, for applications such as health monitoring, health diagnosis, virtual reality and human–machine interfaces. Creating such devices requires components that are soft and stretchable to be mechanically compatible with the human skin.

One of the vital components of skin electronics is an intrinsically stretchable conductor that transmits electrical signals between devices. For reliable operation and high performance, a conductor that features ultrathin thickness, metal-like conductivity, high stretchability and ease of patternability is required — but despite extensive research, so far it has not been possible to develop a material that possesses all of these properties simultaneously.

Led by Professor Hyeon Taeghwan and Kim Dae-Hyeong, IBS researchers unveiled a new method to fabricate a composite material in a form of nanomembrane, which comes with all of the abovementioned properties. The new composite material consists of metal nanowires that are tightly packed in a monolayer within ultrathin rubber film.

The novel material was made using a process that the team developed called a ‘float assembly method’. The float assembly takes advantage of the Marangoni effect, which occurs in two liquid phases with different surface tensions. When there is a gradient in surface tension, a Marangoni flow is generated away from the region with lower surface tension towards the region with higher surface tension. This means that dropping a liquid with lower surface tension on the water surface lowers the surface tension locally, and the resulting Marangoni flow causes the dropped liquid to spread thinly across the surface of the water.

The nanomembrane is created using a float assembly method that consists of a three-step process. The first step involves dropping a composite solution, which is a mixture of metal nanowires, rubber dissolved in toluene and ethanol, on the surface of the water. The toluene-rubber phase remains above the water due to its hydrophobic property, while the nanowires end up on the interface between the water and toluene phases. The ethanol within the solution mixes with the water to lower the local surface tension, which generates Marangoni flow that propagates outward and prevents the aggregation of the nanowires. This assembles the nanomaterials into a monolayer at the interface between water and a very thin rubber-solvent film. In the second step, the surfactant is dropped to generate a second wave of Marangoni flow, which tightly compacts the nanowires. Finally, in the third step, the toluene is evaporated, and a nanomembrane with a unique structure in which a highly compacted monolayer of nanowires is partially embedded in an ultrathin rubber film is obtained.

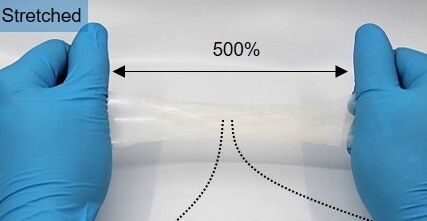

This unique structure allows efficient strain distribution in ultrathin rubber film, leading to excellent physical properties — such as a stretchability of over 1000% and a thickness of only 250 nm. The structure also allows cold welding and bi-layer stacking of the nanomembrane onto each other, which leads to a metal-like conductivity over 100,000 S/cm. Furthermore, the researchers demonstrated that the nanomembrane can be patterned using photolithography, which is a key technology that is widely used for manufacturing commercial semiconductor devices and advanced electronics. Therefore, it is expected that the nanomembrane can serve as a new platform material for skin electronics.

While the study showcased a composite material consisting of silver nanowires within styrene–ethylene–butylene–styrene (SEBS) rubber, it is also possible to use the float assembly method on various nanomaterials such as magnetic nanomaterials and semiconducting nanomaterials, as well as other types of elastomers such as TPU and SIS. Therefore, it is expected that the float assembly can open new research fields involving various types of nanomembranes with different functions.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Hidden semiconductor activity spotted by researchers

Researchers have discovered that the material that a semiconductor chip device is built on,...

3D reflectors help boost data rate in wireless communications

Cornell researchers have developed a semiconductor chip that will enable smaller devices to...

Scientists revolutionise wireless communication with 3D processors

Scientists have developed a method for using semiconductor technology to manufacture processors...