Please do not disturb

By Thomas Rechlin, Senior FAE and Head of Global Application Engineering at RECOM Engineering, Gmunden, Austria

Wednesday, 20 May, 2015

We have all been there. Sitting in the car, listening to our favourite song on the radio. And then the music suddenly turns into a deafening humming and crackling noise. Our eyes turn to our mobile on the dashboard. Seconds later, we receive a call. When thinking about it, we might realise that our experience is due to a highly complex phenomenon, namely electromagnetic interference.

Electromagnetic interference is only one of the areas where filters in DC/DC converters have become a crucial issue. Apart from external interference such as the above electromagnetic interference, transients from upstream supplies and inrush currents, DC/DC converters generate their own interference signals. Inside these devices, power oscillators chop the incoming direct current at a frequency of several 100 kHz, generating low-frequency interference known as ripple and noise. Given that these phenomena are well understood today, why have filters not yet become a standard component of modular converters? Surely, in an age of plug and play, this should not be a difficult task.

The answer is rather predictable: additional components such as filters cost money. And not all applications need to meet the same standards as regards electromagnetic interference. Why pay for a luxury model when the standard one would do? We also must not forget that space on PCBs comes at a premium, and DC/DC converters without costly integrated filter circuits can be implemented in very small housings. While most DC/DC modules feature a simple filter capacitor, there are many applications where such a standard filter solution is simply not sufficient. To cater for such applications, most manufacturers opt for custom-engineered external protection circuits as they tend to be more effective.

EMC - a closed book?

Let us for a moment go back to the example of electromagnetic interference described above. What exactly is electromagnetic compatibility? It is the branch of electrical sciences that studies the unintentional generation, propagation and reception of electromagnetic energy with reference to the unwanted effects. While every electronic device causes what is known as electromagnetic interference, it is also susceptible to external interference. In this context, we speak of interference immunity.

While EMC is in principle a bidirectional phenomenon, manufacturers and operators of DC/DC converters are normally only concerned with the interference caused by the device itself, as the integrated power oscillators are not particularly susceptible to external electromagnetic interference.

In order to identify the most suitable filtering option, we need to distinguish between two types of interference, namely line-bound or conducted interference and radiated interference. As the name implies, conducted interference is propagated through wires. Conventional LC or CLC filter circuits (also known as PI filters) connected to the input provide a highly effective remedy.

They contain current filter chokes known as common mode chokes (CMCs). By adding equal and opposite magnetic fields, they can reduce interference to zero, which in reality is, however, only achieved under ideal conditions. To make this technology work, we need to know the direction of the interference currents in order to choose the right filter choke (common mode or opposite mode).

In contrast to conducted interference, radiated interference is generated purely through electromagnetic fields. While these fields are often produced by lines that act as aerials, they are not bound to the wires and can extend over large distances. To shield a device against the effects of such electromagnetic fields, we must provide large ground surfaces or opt for shielded housings.

The filtering requirements for DC/DC converters are generally determined on the basis of EN 55022 or EN 55015/FCC part 15. Whether a converter must meet the requirements of Class A or the more stringent standards of Class B depends primarily on the envisaged application and operating conditions. Converters designed for universal use should, however, always meet the Class B requirements.

As it has become clear from the above explanations, there is no catch-all solution when it comes to EMC filtering. To come up with a good solution, we need to experiment and trust the experience of experts. There are, however, a few tips and tricks that can be useful when tackling EMC problems (see text box).

Tips and tricks for EMC filtering |

|

Filtering options for low-frequency interference: Low-frequency interference generally occurs in and around cables within a frequency range of up to approx. 1 MHz. It can be effectively prevented with LC filters or CMCs. Filter capacitors close to the input pins are also quite effective. Filtering options for medium-frequency interference: At frequencies of between around 1 and 30 MHz, we normally deal again with line-bound interference. High-frequency LC filters and Y capacitors have been proven effective here. In this case, all interference lines must be short-circuited (eg, with capacitances in the nF range at each pin). Filtering options for high-frequency interference: From around 30 MHz, interference is normally caused through radiation and therefore much more difficult to tackle. Good PCB design with adequate ground surfaces is the key here. If the problem cannot be resolved, additional shielding (eg, six-side shielding) might be the answer. Twisted wires are often helpful in tackling the issue. |

Ripple and noise

The other major issue in relation to DC/DC converter filtering is ripple and noise. While these two terms are commonly mentioned together, they describe actually two different phenomena.

Ripple is caused by the periodic charging and discharging of the output capacitors of the converter. In devices with conventional half-wave rectification, the ripple frequency therefore corresponds to the switching frequency. In more sophisticated circuits with full-wave rectification, the ripple frequency is double the switching frequency. When referring to ripple, most technicians actually mean the output ripple that affects the output voltage. There is, however, a second type of ripple, namely sawtooth waveform interference on the input current. This phenomenon is known as reflected ripple current and must always be taken into account when combining multiple converters in a single circuit.

Noise is a more complex phenomenon with much more random waveforms caused by harmonics. It is produced by switching peaks of transistors/FETs at each switching cycle. The harder/faster the switching of the transistors/FETs, the more noise. When designing a DC/DC converter, engineers need to find an optimum balance between acceptable noise and maximum efficiency.

Figure 1 shows a typical ripple and noise signal. The near-sinusoidal signal is the ripple, while the interference peaks represent the noise. Before we can reduce ripple and noise by filtering, we need to measure these effects accurately. In order to eliminate outside interference, measure as close as possible to the converter and connect the ground barrel of the probe head directly to the ground of the converter (see Figure 2). Otherwise, the cable connections might cause interference signals that affect the measurements. We further recommend setting the bandwidth limitation of the oscilloscope to 20 MHz in order to eliminate high-frequency external interference signals. Always follow the instructions in the data sheet of the measuring equipment manufacturer, as some measurements require an output capacitor (typically 0.1 µF).

Ripple and noise must be measured from peak to peak. For reduction, we recommend an LC filter at the output. Always pay close attention to the properties of the capacitors. Their equivalent serial resistance or ESR should be as low as possible. Capacitors should always be positioned as close as possible to the pin of the converter. Use the two formulas to the right to determine the filter properties. Please note that the filter frequency (fc) should be one-tenth of the operating frequency (fo) of the converter.

Filtering does not stop here

Apart from the two main reasons for filtering, namely EMC and ripple and noise, there are many other interference effects that might require shielding or filtering. Below are two of the most common phenomena.

Inrush current: High inrush currents can damage the converter. These currents are caused by a number of processes in the converter that occur when the device is switched on. At that moment, the built-in capacitors as well as the capacitors at the output filter are charged. The magnetic fields in the transformer cores are built up and the transistors are supplied with maximum power, at least during the first few cycles. The current required to do all this is normally a multiple of the normal input current. It is, however, limited by the input impedance of the converter, the line impedances in the supply cable and the power supply itself. The last factor is normally the most critical here. If the power is taken from a battery, which is capable of supplying very high short-time currents, the converter might become irreparably damaged. To prevent this, DC/DC converters can be equipped with coils near the input, smoothing the inrush current. NTCs (thermistors) have a similar effect and provide excellent protection, especially in AC/DC modules.

Surge protection: Voltage surges known commonly as surges or transients can cause considerable damage to converters. We distinguish between long voltage spikes (in ms range), caused, for example, by instable power supply, and short-term spikes or transients (in µs range) that are typically caused by interference in circuits. Depending on the nature of the surge, varistors or TVS diodes, also known as suppressor diodes, provide good protection. Varistors are the more robust option as they offer protection against high power surges. They have, however, a comparatively long response time. TVS diodes respond more quickly and are therefore particularly suitable to prevent damage from very high voltage spikes (high du/dt ratio).

Power supply competence cluster

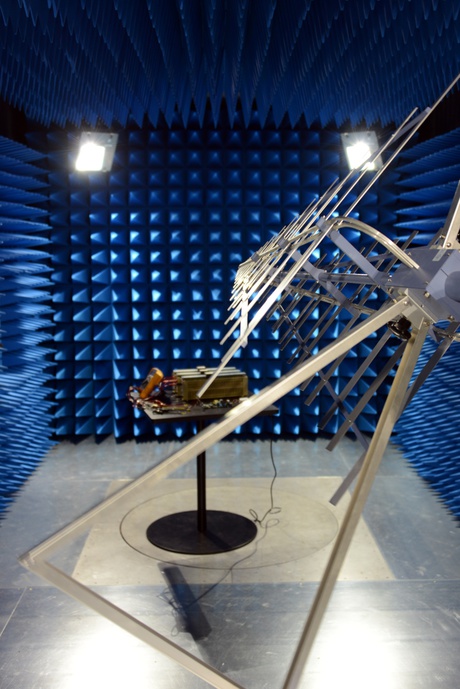

In order to study the effects of interference on converters and other devices in more detail and to help establish a competence cluster in the field of electric power supply, RECOM has invested in a new 3000 m2 campus-like complex that now serves as the company’s headquarters. While the existing research and development, testing and quality laboratories have all been extended, RECOM now also has a state-of-the-art EMC lab, of which there are only very few in Austria and Southern Germany. The 3 m SAR (semi-anechoic room) test chamber enables the company to perform measurements conforming to CISPR22 within a frequency band from 9 kHz to 3 GHz. The chamber caters for the automated measurement of specimens with a diameter of up to 1.5 m. The computer-controlled rotary table and the near-field probes allow engineers to perform fully automated interference tests for critical sources. The lab also includes all the equipment required for measurements according to EN 61000-4-x and EN 61000-3-2.

Compliance with EN 61000-3-2 is particularly important for LED drivers. Last but not least, the in-house GTEM cell enables specialist engineers to determine the radiated immunity of a test specimen. However, the most advanced lab equipment is obviously of no use unless it is operated by qualified personnel. RECOM therefore recruited a highly experienced EMC specialist who is now in charge of the EMC lab.

Hidden semiconductor activity spotted by researchers

Researchers have discovered that the material that a semiconductor chip device is built on,...

3D reflectors help boost data rate in wireless communications

Cornell researchers have developed a semiconductor chip that will enable smaller devices to...

Scientists revolutionise wireless communication with 3D processors

Scientists have developed a method for using semiconductor technology to manufacture processors...