Glass study could lead to shatterproof mobile phone screens

An international study on glass could lead to the development of shatterproof mobile phone screens — a breakthrough (pun not intended) that is sure to result in a collective sigh of relief from clumsy people the world over.

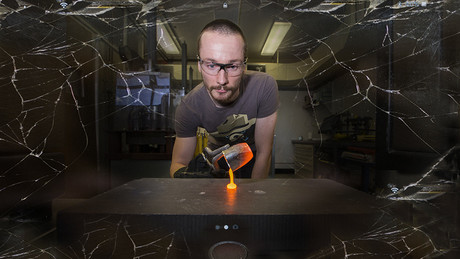

Scientists from Aberystwyth University, the Australian National University (ANU), the Institut de Physique du Globe de Paris (IPGP) and Orléans University have been studying the structure of different types of novel glasses at the atomic level and the way they flow when molten. They have been looking in particular at the structure of alumino-silicate glasses which are used in a range of industrial processes, including the manufacture of screens for handheld devices.

“The glasses we analysed are mostly composed of aluminium and silicon oxides, and can also contain various elements such as sodium, potassium, calcium or magnesium — each element influences the flexibility and resistance of the glass,” said lead researcher Dr Charles Le Losq, from IPGP and ANU. He noted that while glass appears to be structured randomly, it is actually quite ordered at the microscopic level of a few atoms.

“With our new knowledge, industry should be able to alter the glass structure to promote the tiny channels present we have discovered to inhibit propagation of nanometric cracks, to improve the resistance of your cell phone screen to fracture and corrosion,” said Professor Neville Greaves from Aberystwyth University. “This idea is kind of similar to that of drilling a hole at the tip of a crack in a metal sheet to stop the crack in its tracks.”

As part of the research project, the researchers measured the viscosity of molten glass at more than 1000°C and the density of the glass when cooled and formed. The glass’s structure was then simulated by massive computational calculations, enabling the scientists to identify its molecular structure, the exact location of different atoms and the way molten glass flows.

As well as improving glass’s resistance to fractures, the research could lead to better modelling of present volcanic activity and the original formation of Earth and its surface. Another potential application includes the production of highly resistant glasses which imprison radionuclides and could therefore be used to safely store nuclear waste for long periods of time.

The study has been published in the journal Scientific Reports.

Nanoscale pixels to advance augmented reality eyewear

Physicists have developed extremely small pixels that can be used in compact AR glasses, using...

Novel semiconductor shows superconducting promise

Researchers from The University of Queensland have demonstrated superconductivity in...

Light-controlled ferroelectrics for future electronics

Researchers have discovered a way to manipulate the properties of ferroelectric materials quickly...