Liquid metal to fabricate stretchable mini antennas

Researchers have developed a new method for making tiny stretchable antennas from hydrogel and liquid metal. The antennas could be used in wearable and flexible wireless electronic devices to provide a link between the device and external systems for power delivery, data processing and communication.

Tao Chen from Xi’an Jiaotong University in China said the researchers used a new fabrication approach to demonstrate that the length of a liquid metal antenna can be cut in half. “This may help downsize wearable devices used for health monitoring, human activity monitoring, wearable computing and other applications, making them more compact and comfortable,” Chen said.

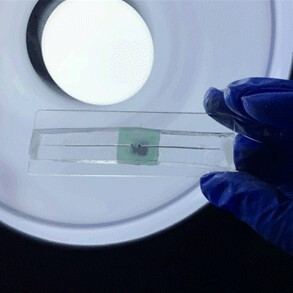

In the journal Optics Express, the researchers described their new technique, which involves injecting eutectic gallium-indium — a metal alloy that is a liquid at room temperature — into a microchannel created with a single-step femtosecond laser ablation process. They used this method to create an antenna measuring 24 x 0.6 x 0.2 mm embedded into a 70 x 12 x 7 mm hydrogel slab.

Stretchable and flexible antennas could be useful for wearable medical devices that monitor temperature, blood pressure and blood oxygen. “Separate mobile devices could connect to a larger control unit via the flexible antennas — which would transfer data and other communications — forming a wireless body-area network. Since the resonance frequencies of the flexible antennas vary with applied strain, they could potentially also be used as a wearable motion sensor,” Chen said.

The work grew out of previous research, in which the investigators developed a way to fabricate 3D silver structures embedded in hydrogel for strain sensing using femtosecond laser ablation. “The silver structures exhibited poor stretchability because they were very fragile. Using liquid metal instead of a solid metal structure not only makes the metal easier for filling the hydrogel microchannel but increases its ability to stretch,” Chen said.

To make a liquid metal dipole antenna, the researchers scanned a femtosecond laser to form a pair of symmetrical microchannels inside a hydrogel without harnessing the surface. The laser’s short pulse duration produces a high peak power that allows ablation of transparent material via nonlinear optical effects like multiphoton absorption, which ensures that ablation only takes place at the precise focal point for the laser. The researchers then injected the liquid metal into the microchannels, forming a hydrogel-embedded wire that can be used as an antenna.

The researchers selected hydrogel as a substrate because it has more favourable dielectric properties compared to polydimethylsiloxane (PDMS) and other conventional polymer substrates, allowing the length of the antenna to be reduced by half. Hydrogel-based devices can also be stretched to almost double their original length. However, hydrogel-based liquid metal devices are fabricated using a laser to engrave grooves on the top surface, filling them with liquid metal and then bonding the patterned substrate with an unengraved substrate.

“Using our method, the microchannel can be embedded in hydrogel using a single fabrication step with no need for layer bonding. In addition, 3D microchannels as well as liquid metal structures can be easily formed by 3D scanning the femtosecond laser, which makes it possible to fabricate 2D or 3D flexible antennas with complicated structures for performance and function enhancement,” Chen said.

The researchers are now working to improve the sealing technique used on the laser-induced microchannels to increase the strength of the flexible stretchable antenna and the threshold strain of liquid metal leaking. They also plan to explore how this new approach could be applied to develop fully flexible multidimensional strain and pressure sensors with complicated 2D or 3D structures.

Fully coupled annealing processor for enhanced problem solving

Researchers have designed a scalable, fully-coupled annealing processor with 4096 spins, and...

STMicroelectronics breaks 20 nm barrier for next-gen microcontrollers

STMicroelectronics has launched an advanced process based on 18 nm Fully Depleted Silicon On...

Chip opens door to AI computing at light speed

A team of engineers have developed a silicon-photonics chip that uses light waves, rather than...