Start-up reinvents lithium-ion battery manufacturing process

A new manufacturing approach for lithium-ion batteries is said to significantly reduce the manufacturing cost.

The new battery design, developed by researchers at MIT and at spinoff company 24M, is a hybrid between flow batteries and conventional solid ones — in this version, while the electrode material does not flow, it is composed of a similar semisolid, colloidal suspension of particles.

The approach is based on a concept developed five years ago by Yet-Ming Chiang, the Kyocera Professor of Ceramics at MIT and colleagues including W Craig Carter, the POSCO Professor of Materials Science and Engineering. In this so-called ‘flow battery’, the electrodes are suspensions of tiny particles carried by a liquid and pumped through various compartments of the battery.

This approach greatly simplifies manufacturing, and also makes batteries that are flexible and resistant to damage, said Chiang, who is senior author of a paper in the Journal of Power Sources analysing the trade-offs involved in choosing between solid and flow-type batteries, depending on their particular applications and chemical components.

This analysis demonstrates that while a flow-battery system is appropriate for battery chemistries with a low energy density (those that can only store a limited amount of energy for a given weight), for high-energy-density devices such as lithium-ion batteries, the extra complexity and components of a flow system would add unnecessary extra cost.

Almost immediately after publishing the earlier research on the flow battery, Chiang said, “We realised that a better way to make use of this flowable electrode technology was to reinvent the [lithium-ion] manufacturing process.”

Instead of the standard method of applying liquid coatings to a roll of backing material, and then having to wait for that material to dry before it can move to the next manufacturing step, the new process keeps the electrode material in a liquid state and requires no drying stage at all. Using fewer, thicker electrodes, the system reduces the conventional battery architecture’s number of distinct layers, as well as the amount of non-functional material in the structure, by 80%.

Having the electrode in the form of tiny suspended particles instead of consolidated slabs greatly reduces the path length for charged particles as they move through the material — a property known as ‘tortuosity’. A less tortuous path makes it possible to use thicker electrodes, which, in turn, simplifies production and lowers cost.

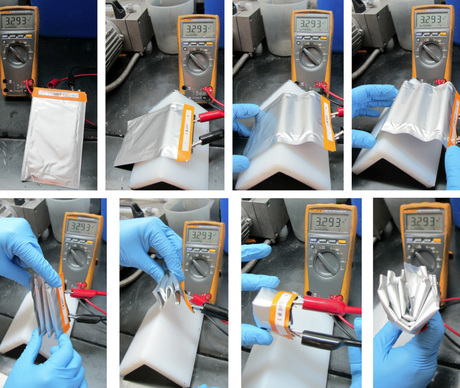

In addition to streamlining manufacturing enough to cut battery costs by half, Chiang said, the new system produces a battery that is more flexible and resilient. While conventional lithium-ion batteries are composed of brittle electrodes that can crack under stress, the new formulation produces battery cells that can be bent, folded or even penetrated by bullets without failing. This should improve both safety and durability, he said.

The company has so far made about 10,000 batteries on its prototype assembly lines, most of which are undergoing testing by three industrial partners, including an oil company in Thailand and Japanese heavy-equipment manufacturer IHI Corp. The process has received eight patents and has 75 additional patents under review; 24M has raised $50 million in financing from venture capital firms and a US Department of Energy grant.

The company is initially focusing on grid-scale installations, used to help smooth out power loads and provide backup for renewable energy sources that produce intermittent output, such as wind and solar power. But Chiang said the technology is also well suited to applications where weight and volume are limited, such as in electric vehicles.

Another advantage of this approach, Chiang said, is that factories using the method can be scaled up by simply adding identical units. With traditional lithium-ion production, plants must be built at large scale from the beginning in order to keep down unit costs, so they require much larger initial capital expenditures. By 2020, Chiang estimates that 24M will be able to produce batteries for less than $100 per kWh of capacity.

In addition to Chiang, the Power Sources paper was co-authored by graduate student Brandon Hopkins, mechanical engineering professor Alexander Slocum and Kyle Smith of the University of Illinois at Urbana-Champaign. The work was supported by the US Department of Energy’s Center for Energy Storage Research, based at Argonne National Laboratory in Illinois.

Novel material improves stability, efficiency of PSCs

A team of chemists has developed a new material for perovskite solar cells that can be used as a...

Device gathers, stores electricity in remote settings

New research shows the pyroelectrochemical cell, or PEC, harnesses changes in ambient temperature...

Fast-charging lithium battery seeks to eliminate "range anxiety"

Researchers at Cornell University have developed a lithium battery with fast charging...