Three reasons to incorporate proper ergonomics

Posture has become an important part of ergonomics, which is the concept of using items to position the body in a more efficient and safe manner.

The term ergonomics is used in a variety of contexts, usually to convey the idea of someone being comfortable. There’s a great business case for proper posture and ergonomics.

1. Enhanced productivity

One of the primary concepts of ergonomics is keeping tools within easy reach. Think of it like a mechanic having a toolbox in the reception area instead of the shop floor. How much time would be wasted going back and forth to get the right tool? Having the tools necessary to do one’s job in an easily accessible area can reduce the time it takes to complete a task, thereby improving productivity.

Another important factor in increasing productivity is prevention of repetitive injuries. Performing the same or similar tasks for prolonged periods of time with poor posture and excessive reaching/straining can result in aches and injuries. In 2013, the US Bureau of Labor Statistics reported that work-related musculoskeletal disorders (MSDs) accounted for roughly one-third of all worker injury and illness cases. MSDs can affect various parts of the body, such as muscles and ligaments, and these injuries include tendinitis, carpal tunnel and muscle strains. Depending on the severity of the MSD, a worker could require rest, physical therapy and sometimes even surgery to remedy the pain. This can result in the worker unable to perform their job to full capacity, or even absenteeism.

2. Higher-quality work

Without being distracted by something like a nagging ache in the back or neck, employees are able to better focus on their work. Attentiveness leads to a better quality of work, which leads to a better-quality product.

Product quality can also be influenced by the work atmosphere. It is important for companies to demonstrate that they value the time, effort and livelihood of their employees. Using proper ergonomic strategies and equipment setups to eliminate the aches and pains associated with poor workplace ergonomics can improve an individual’s demeanour, which improves company morale. Generally speaking, a healthy worker is a happy worker.

3. Regulatory compliance

In some countries, ergonomics is included in the local or regional workplace health and safety regulations that fall under the purview of the government. Companies that have incident rates higher than the industry average can make a business case for ergonomic improvements. Why continuously pay out for ergonomic-related incidents when you could devise and pay for a solution to reduce those incidents and their associated costs? Incorporating better ergonomics into the workplace can reduce costs. Poor ergonomics can contribute to MSDs, and these injuries can cost companies in worker compensation payouts and injury benefits. From an economic perspective, ergonomic workplaces should be seen as a good investment.

Since workplace ergonomics are paramount in preserving employee health and productivity, the US Center for Disease Control and Prevention’s (CDC) National Institute for Occupational Safety Health (NIOSH) developed a program to evaluate and resolve ergonomics issues in the work environment. The Elements of Ergonomics Program utilises seven vital steps to prevent work-related MSDs. These steps include actions such as signage to warn workers of common repetitive injuries, organisational changes to address known problems and prevent future issues, training to educate management and workers on recognising risk factors of potential causes of MSDs, and identifying controls for duties that are high-risk for injuries.

Implementing change

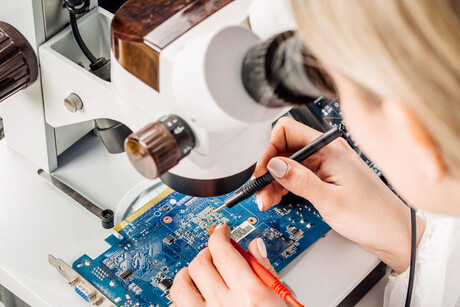

Solutions to the problem of poor ergonomics don’t have to be an involved process. Let’s use industrial microscopy as an example. It is crucial that routine microscopists — users who operate a microscope for at least half of their workday — practise proper ergonomics to maintain their health and safety.

One of the easiest ways to incorporate proper ergonomics is to ensure tools are within easy reach. In microscopy, that can be as simple as placing the microscope near the edge of the table.

The next step is to maintain a neutral position. This includes keeping a straight back, only a minor tilt of the neck and a level line of sight.

It’s important to maintain that posture and avoid hunching over, which is a habit that could take some time for employees to adopt. Ergonomic posture further includes keeping elbows close to one’s obliques, placing arms on the table at roughly a right angle, and placing feet flat on the floor when operating a microscope while sitting down.

Placing the stereo microscope on an adjustable standing desk gives employees the option to alternate between sitting and standing. Switching positions while working, even if it is just shifting one’s weight slightly, is important for ergonomics to relieve muscle tension.

Taking short breaks is advised in most occupations that involve sitting at a desk and repetitive tasks. To help avoid stiffness, employees should pause and readjust their position every one to two hours. In the case of microscopy, this has the added benefit of changing employees’ eye focus, which should actually be done every 30 minutes. Shifting focus will help avoid eye strain and prevent headaches.

Find the right equipment provider

The equipment used by employees is an essential component in ergonomics. An equipment provider that is looking out for a business’s best interest is one that places an emphasis on ergonomics. With stereo microscopes, for example, a good provider understands that there is no one-size-fits-all approach and has a variety of options and adjustable components to choose from to accommodate any operator.

There’s a lot to gain, and save, through proper ergonomics. That’s why finding the right equipment provider is essential.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletters and bimonthly magazine.

Originally published here.

Avoiding EMC issues: simple tests you can do yourself

This is a brief overview of EMC compliance with some practical tips on not getting caught out.

Electric dump valves help oil and gas company reduce emissions

Oil and gas company Laramie Energy deployed ASCO zero-emissions electric dump valves to comply...

Australia's largest electronics expo returns to Sydney

Electronex, the annual electronics design and assembly expo, will return to Sydney on 19–20...