Flexible optical sensor detects pressure and location

Researchers from Keio University in Japan have developed a flexible optical touch sensor that can detect the strength and location of pressure with high sensitivity and stability.

The advance in tactile sensing paves the way for next-generation robotic touch surfaces, highly responsive wearable electronics and advanced medical diagnostics.

“Unlike conventional optical tactile sensors, which tend to have a single input-output path, our sensor design achieves multiple optical channels by embedding polymer optical waveguides in silicone rubber,” said research team leader Takaaki Ishigure. “This makes it possible to detect pressure in more than one spot with a design that is scalable and adaptable to various applications.”

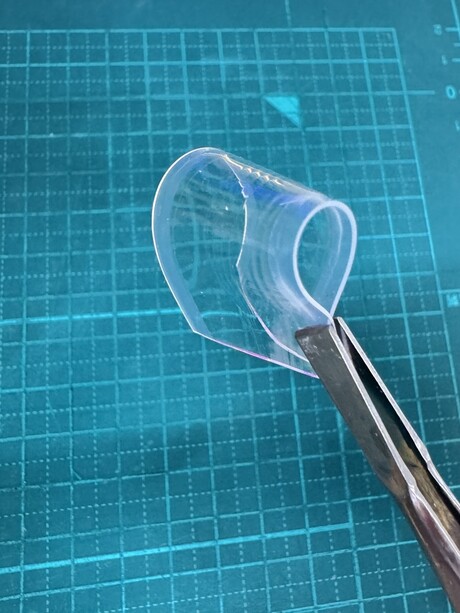

In the journal Optics Express, the researchers detailed the fabrication of a four-channel optical tactile sensor measuring 5 x 1.5 centimetres and 500 microns thick. The research findings indicate that the optical tactile sensor can detect pressure positions with a spatial resolution of approximately 1.5 mm.

The paper’s first author, Yuantian Yin, said this technology could give robotic systems high-precision touch, for safer and more intuitive human–robot collaboration.

Although other research groups have demonstrated thin, flexible tactile sensors by embedding commercial glass optical fibres into polymer sheets, these designs typically have a single optical path. This means that complex, rigid wiring arrangements must be used to achieve the multi-channel configurations necessary for pressure sensing from more than one location.

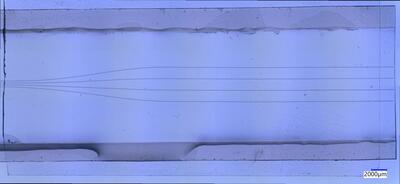

To create an optical tactile sensor with multiple optical channels, the researchers used a method they previously developed for fabricating polymer optical waveguides. Known as the Mosquito method, it uses a syringe to inject a liquid resin monomer into another that has been spread into a thin sheet on a substrate.

The liquids are then UV-cured to solidify the materials. This approach makes it possible to create 3D core wiring and circular cores like the ones found in traditional optical fibres, which are difficult to produce using conventional major fabrication methods.

“With the Mosquito method, we formed polymer cores within a sheet of flexible silicone rubber known as PDMS in one step, greatly increasing the flexibility of the waveguide structural design,” Ishigure said. “This method allows us to control how the light is guided, and thus the sensor’s sensitivity, by adjusting properties such as confinement and core size. This would not be possible with commercial optical fibres that have fixed properties.”

Using the Mosquito fabrication method, the researchers created multiple thin light paths inside a thin sheet of PDMS to create an optical touch sensor. When no pressure is applied, the light transmits through all the paths until it reaches the output side of the sheet. However, when a point on the sheet’s surface is pressed, the area around that point becomes compressed, causing the light path underneath the point to bend.

If the bend is sharp enough, some light leaks from the path, which decreases the light intensity. By monitoring which light paths get dimmer and by how much, it is possible to determine where the pressure was applied and how strong it was, making distributed tactile sensing possible.

To test the sensor, the researchers applied controlled pressure with a fingertip or a force gauge while monitoring the optical output. The sensor detected fingertip pressure that was roughly the same as when tapping an icon on a smartphone screen and demonstrated pressure sensitivities of 8.7 to 10.9 dB/MPa. It also detected changes in light intensity within 33 ms, recovered well after repeated cycles and pinpointed pressure positions with a spatial resolution of about 1.5 mm. According to the researchers, these results confirmed the sensor’s high sensitivity, reliability and repeatability.

Future work will focus on improving the spatial resolution of the sensor and further extending it to 3D cross-waveguide structures to achieve large-area, multi-point, high-density distributed tactile perception. The team also plans to refine the fabrication process to lower costs and improve integration, while exploring real-world applications in human–machine interaction.

Fingertip bandage brings texture to touchscreens

Researchers have developed a haptic device that enables wearers to feel virtual textures and...

Sweat sensor sticker monitors vitamin C in real time

Researchers have developed a battery-free electronic sticker designed to monitor vitamin C levels...

Wearable sensor monitors sweat in real time

Researchers have developed a non-invasive, wearable sensor that can identify and track lactate in...