How to master power density for motor drives

Reducing system cost by maximising the output power density is one of the major demands on power modules today, especially in cost-sensitive market segments like motor drive applications.

One key to more power is optimising the thermal resistance layer between the chip and heatsink. SEMIKRON has several options to achieve the highest possible power density to increase the output current capability by more than 30%, while using the same physical chipset and power module size.

SEMIKRON’s MiniSKiiP series has become a standard for compact motor drives of low to medium power. The baseplate-less modules are available in a range of 4 to 400 A with blocking voltages up to 1700 V in six-pack, CIB topologies, with the rectifier, brake chopper and inverter as well as half bridges with separate rectifier modules. MiniSKiiP provides an advantage through its scalability over the full power range and its one/two-screw mounting concept: in just one mounting process, a complete subsystem can be assembled with the power module, heatsink, power PCB with DC bus capacitors, line and motor connection terminals, and current sensors. Another advantage of MiniSKiiP is the high quality level: every single module leaving the factory is 100% electrically tested during production.

More than 30 million MiniSKiiP modules have been sold, most powering motor drives all over the world while helping to build more compact solutions. But how can costs be further optimised? The answer is by improving the power density through reducing the thermal impedance of the power system.

The biggest portion of the thermal resistance from chip to heatsink (Rth(j-s)) is taken up by the thermal interface material (TIM or thermal grease), with an approximately 50% share. Thus it makes sense to focus on improving that layer first.

The main task of the TIM is the thermal interconnection of two surfaces by smoothing out the module’s bottom and the heatsink’s roughness with a minimum layer thickness. Figure 1 shows how the different composition layers contribute with single resistance values to the overall thermal resistance of the TIM layer, Rth,TIM.

Various ranges of TIMs on the market promise a state-of-the-art thermal performance, and the majority of users pay attention to the datasheet value for the thermal conductivity only. But in fact, this value is only relevant for the thermal resistance of the bulk layer Rth,bulk.

As an example, pads and foils often provide a high thermal conductivity in the vertical direction and the materials are usually stiff compared to pastes, meaning they are not able to sufficiently fill the roughness and bending in micrometre range. So even though the thermal conductivity of TIM materials can be high, and thus the thermal bulk resistance Rth,bulk low, the total thermal resistance for the TIM layer will not be optimal due to increased contact resistances Rth,contact.

Why does one paste perform better than another and surely better than a thermal pad? The answer is in the composition of the TIM with its two main components: the filling material (particles) as the thermally conductive material and the matrix as a carrier material, responsible for the wettability. For the Rth,bulk the filling degree is the most important factor, while the thermal conductivity of the single particle has less impact. The filling degree describes the volume of conductive material inside a compound. However, the Rth,contact of the contact layers close to the metal surfaces is mainly defined by the particle size and the size distribution of these particles.

Therefore, for an optimum overall thermal resistance Rth,TIM the filling degree, particle size, particle size distribution and, with less importance, thermal conductivity of the particles have to be optimised. SEMIKRON has done this with its High Performance Thermal Paste (HPTP).

The correlation of filling degree and overall performance is also visible for the HPTP: the data sheet value for the thermal conductivity is average while the thermal performance when applied to the power module is superior, as discovered through a comprehensive benchmark test SEMIKRON performed.

Beside these factors, the power module and its mounting conditions also have a significant influence on the HPTP performance. An optimisation of the thickness and distribution of the thermal paste therefore has to be achieved for every power module type.

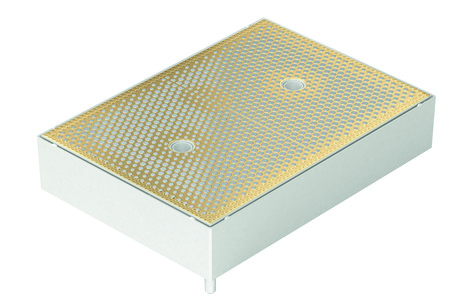

SEMIKRON has been printing TIM on power modules for more than 20 years, with more than 10 million pre-printed power modules in the field. SEMIKRON HPTP is available on several power modules; Figure 2 shows the bottom side of a MiniSKiiP with an optimised printing pattern. Every pre-printed module undergoes a comprehensive qualification program ensuring the long-time stability and performance of the TIM in the application as well as the shelf life before mounting. Along with industrial applications, more challenging requirements are also fulfilled, ie, automotive standards.

The second biggest portion of the overall Rth(j-s) is the ceramic material, and here optimisation also makes sense. Alternatives to aluminium oxide (Al2O3) direct bonded copper (DBC) substrates used today are widely available. Considering thermal and mechanical parameters silicon nitride (Si3N4) AMB (active metal brazing) ceramics represents an ideal candidate, having four times higher thermal conductivity and significantly higher figures for the main mechanical characteristics when compared to Al2O3: eg, the bending strength value is 650 MPa compared to Al2O3’s 450 MPa and the fracture toughness is at least 7 MPa/(m-1) compared to 4.2 MPa/(m-1). The brazing process also guarantees higher durability of the copper/ceramic joint, thus improved durability against thermal cycling.

With new materials used for optimisation, new qualification and testing specifications are also required. The AMB production process of Si3N4 substrates requires a brazing metallisation layer, which usually includes silver too.

Silver can migrate under the influence of humidity and an electric field generated by a high DC voltage — both conditions that commonly occur in power modules. This silver migration would result in a visible change of the substrate surface: a dendritic appearance of the migrating silver in the isolation trenches (see Figure 3). The standard test ‘High Voltage High Humidity, High Temperature Reverse Bias’ (HV-H3TRB) will stimulate this effect.

To confirm that this effect has no negative impact on the product within the lifetime of the application, a newly introduced ‘accelerated lifetime’ test has been performed. This test reproduces real working conditions and is used to ensure reliability. The power modules are operated under climatic change, alternating between -15 and 85°C and a relative humidity of 10% and 85% with 10 cycles and 12 hours per cycle. The modules are supplied with 540 VDC bus voltage and switch with 1 kHz of carrier frequency, without failure.

Figure 4 shows the benefits regarding Rth(j-s) and output current capability. Based on a MiniSKiiP housing size 3 with six-pack topology, a typical motor drive application has been simulated. Just replacing the standard TIM with HPTP on the existing module using Al2O3 substrate, the Rth(j-s) is reduced by 34%. Considering a standard motor drive application operating 4 kHz with an overload of 200% for 10 s, the result is a remarkable 20% higher output current at the same junction operation temperatures.

If the Al2O3 substrate is additionally replaced with Si3N4 using the HPTP, the Rth(j-s) is reduced by as much as 54% boosting the output power and therefore power density of the module by 34%.

We can see that the combination of state-of-the-art thermal interface material and substrate technology within the power modules boosts the output performance of a motor drive’s application drastically. And all of this without compromising the lifetime of the module.

Diamond thermal management for high-power electronics

Researchers have unveiled a scalable method to grow patterned diamond films directly on wafers,...

What does cybersecurity look like in the quantum age?

As quantum computers are increasingly integrated into daily life, it will become critical to...

Transforming acoustic waves with a chip

Researchers have developed a chip that uses on-chip phased interdigital metamaterials to shape...