Automating semiconductor research with machine learning

The development of new thin semiconductor materials requires a quantitative analysis of a large amount of reflection high-energy electron diffraction (RHEED) data, which is time-consuming and requires expertise. To tackle this issue, scientists have identified machine learning techniques that could help automate RHEED data analysis, accelerating semiconductor research in the process.

The semiconductor industry has been growing steadily ever since its first steps in the mid-20th century, and today there is a growing need for faster, more integrated and more energy-efficient semiconductor devices. However, modern semiconductor processes have already reached the nanometre scale, and the design of novel high-performance materials now involves the structural analysis of semiconductor nanofilms.

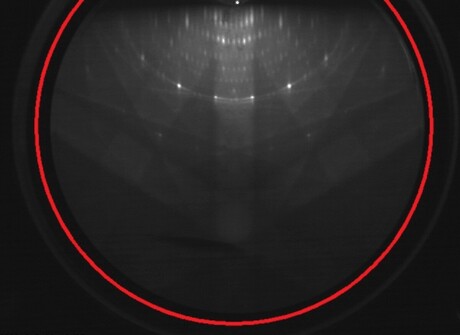

RHEED is a widely used analytical method that can be used to determine the structures that form on the surface of thin films at the atomic level and can even capture structural changes in real time as the thin film is being synthesised. Unfortunately, RHEED is sometimes hindered by the fact that its output patterns are complex and difficult to interpret. In virtually all cases, a highly skilled experimenter is needed to make sense of the huge amounts of data that RHEED can produce in the form of diffraction patterns.

Now, Japanese researchers have explored the possibility of using machine learning to automatically analyse RHEED data. This work was led by Dr Naoka Nagamura, a visiting associate professor at the Tokyo University of Science (TUS) and senior researcher at Japan’s National Institute for Materials Science (NIMS), with results published in the journal Science and Technology of Advanced Materials: Methods.

The researchers focused on the surface superstructures that form on the first atomic layers of clean single-crystal silicon — one of the most versatile semiconductor materials — depending on the amount of indium atoms adsorbed and slight differences in temperature. Surface superstructures are atomic arrangements unique to crystal surfaces where atoms stabilise in different periodic patterns than those inside the bulk of the crystal, depending on differences in the surrounding environment. Because they often exhibit unique physical properties, surface superstructures are the focus of much interest in materials science.

First, the team used different hierarchical clustering methods, which are aimed at dividing samples into different clusters based on various measures of similarity. This approach serves to detect how many different surface superstructures are present. After trying different techniques, the researchers found that Ward’s method could best track the actual phase transitions in surface superstructures.

The scientists then sought to determine the optimal process conditions for synthesising each of the identified surface superstructures. They focused on the indium deposition time for which each superstructure was most extensively formed. Principal component analysis and other typical methods for dimensionality reduction did not perform well. Fortunately, non-negative matrix factorisation, a different clustering and dimensionality reduction technique, could automatically obtain the optimal deposition times for each superstructure.

“Our efforts will help automate the work that typically requires time-consuming manual analysis by specialists,” Nagamura said. “We believe our study has the potential to change the way materials research is done and allow scientists to spend more time on creative pursuits.”

Overall, the findings reported in this study should lead to new and effective ways of using machine learning techniques for materials science ― a central topic in the field of materials informatics. In turn, this would have implications in our everyday lives as existing devices and technologies are upgraded with better materials.

“Our approach can be used to analyse the superstructures grown not only on thin-film silicon single-crystal surfaces, but also metal crystal surfaces, sapphire, silicon carbide, gallium nitride and various other important substrates,” Nagamura said. “Thus, we expect our work to accelerate the research and development of next-generation semiconductors and high-speed communication devices.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Light reshapes semiconductors for advanced optical devices

Researchers have shown how light reshapes Janus semiconductors at the atomic scale, enabling...

Novel method to grow ultrathin semiconductors on electronics

Researchers have developed a technique that could speed up the development of next-generation...

Blue LEDs developed to enhance display performance

Researchers have developed a new method for manufacturing light-emitting diodes (LEDs) that emit...