Graphite-coated relays can withstand harsh environments

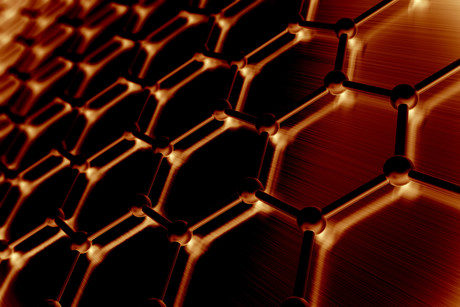

UK researchers have created microelectromechanical relays suitable for harsh environments — by coating the contacts with nanocrystalline layers of graphite.

Micro- and nanoelectromechanical relays have effectively zero leakage current and can operate at much higher temperatures and levels of radiation than solid-state transistors. Such miniaturised relays have the potential to realise smart electronic components with integrated sensing, processing and actuation that are energy efficient.

Now, researchers at the Universities of Bristol and Southampton, in collaboration with semiconductor supplier Microsemi, have demonstrated how films of nanocrystalline graphite with a thickness of tens of nanometres can protect the relay tips against degradation over millions of switching cycles and provide a reliable electrical contact. Their work has been published in the journal Carbon.

“This is a breakthrough result that could pave the way for a new class of extremely energy-efficient electronic components for use in emerging paradigms such as autonomous sensor nodes in the Internet of Things,” said Dr Dinesh Pamunuwa, corresponding author on the paper from the University of Bristol.

“The relays can withstand temperatures over 225°C and can easily absorb radiation doses that are two orders of magnitude higher than transistors are able to withstand. The challenge has been to make them reliable, and these thin films of nanocrystalline graphite effectively act as a conducting solid lubricant, protecting the relay electrodes as they physically make and break contact millions of times.”

Dr Pamunuwa has been working on development of nanoelectromechanical relays for digital applications for over seven years. The work has been supported by the UK Government through grants from the Defence Science and Technology Laboratory (Dstl) and Innovate UK, as well as the EU.

Red OLED microdisplay for energy-efficient AR/VR

Researchers have developed a CMOS-based red OLED microdisplay with luminance and improved power...

Next-gen semiconductor material for light-based electronics

Scientists from the University of Edinburgh have created a new type of material that could enable...

Chip-scale optical amplifier enhances data and sensing

Energy-efficient and small enough to fit in a smartphone, an optical amplifier developed at...