Micro-LEDs stacked vertically to sharpen displays

Current flat panel displays for virtual reality use pixels that are visible to the naked eye, along with small bits of unlit dark space between each pixel that can appear as a black, mesh-like grid. Researchers from the Georgia Institute of Technology, in collaboration with researchers from the Massachusetts Institute of Technology (MIT) have developed a new process based on 2D materials to create LED displays with smaller and thinner pixels. Enabled by two-dimensional, materials-based layer transfer technology, the innovation could ultimately lead to clearer and more realistic LED displays.

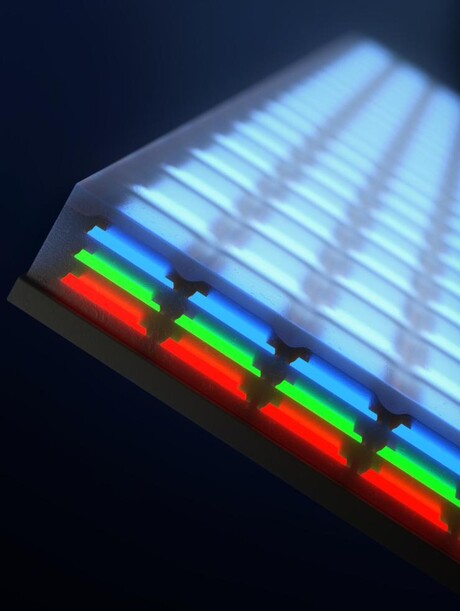

The researchers published a paper in the journal Nature, with co-authors from Sejong University in Korea and from additional institutions in the US and South Korea. Georgia Tech-Europe Professor Abdallah Ougazzaden and research scientist Suresh Sundaram collaborated with researchers from MIT to improve the current conventional LED manufacturing process. Instead of using prevailing processes based on laying red, green and blue (RGB) LEDs side by side, which limits pixel density, the team vertically stacked freestanding, ultrathin RGB LED membranes, achieving an array density of 5100 pixels per inch — the smallest pixel side reported to date (four microns) and reportedly the smallest stack height — all while delivering a full commercial range of colours. This ultra-small vertical stack was achieved via the technology of van der Waals epitaxy on 2D boron nitride developed at the Georgia Tech-Europe lab and the technology of remote epitaxy on graphene developed at MIT.

The study showed that thin and small pixelled displays can be enabled by an active layer separation technology using 2D materials such as graphene and boron to enable high array density micro-LEDs resulting in full-colour realisation of micro-LED displays. The two-dimensional, material-based layer transfer (2DLT) technique allows the reuse of epitaxial wafers; reusing this costly substrate could lower the cost for manufacturing smaller, thinner and more realistic displays.

“We have now demonstrated that this advanced 2D, materials-based growth and transfer technology can surpass conventional growth and transfer technology in specific domains, such as in virtual and augmented reality displays,” said Ougazzaden, the lead researcher for the Georgia Tech team.

These techniques were developed in metalorganic chemical vapour disposition (MOCVD) reactors, a key tool for LED production at the wafer scale. The 2DLT technique can be replicated on an industrial scale with high throughput yield. The technology has the potential to bring the field of virtual and augmented reality to the next level, enabling the next generation of immersive, realistic micro-LED displays.

“This emerging technology has a tremendous potential for flexible electronics and the heterogeneous integration in opto-electronics, which we believe will develop new functionalities and attract industry to develop commercial products from smartphone screens to medical devices,” Ougazzaden said.

Red OLED microdisplay for energy-efficient AR/VR

Researchers have developed a CMOS-based red OLED microdisplay with luminance and improved power...

Next-gen semiconductor material for light-based electronics

Scientists from the University of Edinburgh have created a new type of material that could enable...

Chip-scale optical amplifier enhances data and sensing

Energy-efficient and small enough to fit in a smartphone, an optical amplifier developed at...