Pure red LEDs made from nitride semiconductors

Pure red LEDs are vital for building the next generation of energy-efficient micro-LED displays to follow OLED displays and for creating lighting with colour tuning — but making such LEDs from nitride crystals is a goal that has so far been difficult. Now electrical engineers from King Abdullah University of Science and Technology (KAUST) have found a solution, as published in the journal Applied Physics Express.

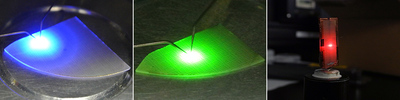

“Electrical engineers can already make bright LEDs using varying materials to produce different colours. But to improve display technologies, engineers must integrate the three primary colour LEDs — red, green and blue — onto one chip,” said Daisuke Iida, an electrical engineer at KAUST.

This means engineers need to find one material that is suitable for manufacturing all three colours. The material should be able to produce each colour with high intensity, and ideally it should have a high-power output but use relatively little battery voltage.

The best candidates for generating all three colours are a family of compounds called nitride semiconductors. These are crystals containing nitrogen that in theory can be used to create LEDs that produce light with wavelengths between ultraviolet and infrared, which includes the entire visible spectrum. Engineers usually use gallium nitride to make blue and green LEDs, but they have struggled to make bright red LEDs with this crystal.

“Red vision has been almost impossible — other groups have only really succeeded in making orange, not apple red,” said research group leader Kazuhiro Ohkawa. “Now, we have developed a crystal growth system to realise pure red LEDs.”

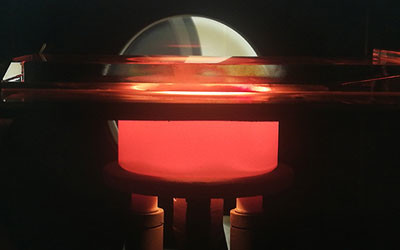

Replacing a large portion of the gallium with the element indium gives the desired red, but it is hard to do because indium easily evaporates from the crystal. So Iida, Ohkawa and colleagues created a reactor with extra indium vapour above the crystal’s surface — a process known as metalorganic vapour-phase deposition. This added pressure prevents the indium in the crystal from escaping.

“This gives us a higher indium concentration at the surface,” Ohkawa said. “That’s our secret!”

But there was another hurdle to overcome. Indium is made of larger atoms than gallium, so when it is introduced, it creates defects in the crystal, degrading the quality of output light. The team’s trick was to also add aluminium, which has small atoms.

“The introduction of the small atoms reduces the strain on the crystal, resulting in fewer crystal defects,” Iida said.

“Another advantage is that the LEDs operate at about half the voltage of its competitors,” Ohkawa added. “This will give you a longer lifetime for batteries.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Red OLED microdisplay for energy-efficient AR/VR

Researchers have developed a CMOS-based red OLED microdisplay with luminance and improved power...

Next-gen semiconductor material for light-based electronics

Scientists from the University of Edinburgh have created a new type of material that could enable...

Chip-scale optical amplifier enhances data and sensing

Energy-efficient and small enough to fit in a smartphone, an optical amplifier developed at...