Technique developed to prevent bipolar degradation in silicon carbide electronics

Silicon carbide (SiC) is a semiconductor material that can outperform pure silicon-based semiconductors in some applications. Used mostly in power inverters, motor drives and battery chargers, SiC devices offer benefits such as a high power density and reduced power losses at high frequencies even at high voltages. Although these properties and its relatively low cost make SiC a promising contender in various sectors of the semiconductor market, its poor long-term reliability has been a barrier. A pressing issue with 4H-SiC — a SiC type with superior physical properties — is bipolar degradation. This is caused by the expansion of stacking faults in 4H-SiC crystals. Small dislocations in the crystal structure grow over time into large defects called ‘single Shockley stacking faults’ that progressively degrade performance and cause the device to fail. Although some methods to mitigate this problem exist, they make the device fabrication process more expensive.

Researchers from Japan, led by Associate Professor Masashi Kato from the Nagoya Institute of Technology, have found a feasible solution for this issue. In their study, published in the journal Scientific Reports, they present a fault suppression technique called “proton implantation” that can prevent bipolar degradation in 4H-SiC semiconductor wafers when applied prior to the device fabrication process. According to Kato, dipolar degradation even exists in the substrate layers of recently developed SiC epitaxial wafers. “We wanted to help the industry navigate this challenge and find a way for developing reliable SiC devices, and, therefore, decided to investigate this method for eliminating bipolar degradation,” Kato said.

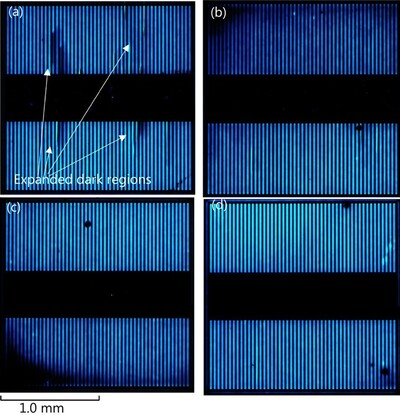

Proton implantation involves ‘injecting’ hydrogen ions into the substrate using a particle accelerator; the idea is to prevent the formation of single Shockley stacking faults by pinning down partial dislocations in the crystal, one of the effects of introducing proton impurities. However, proton implantation itself can damage the 4H-SiC substrate, due to which high-temperature annealing is used as an additional processing step to repair this damage. The research team aimed to verify if proton implantation would be effective when applied before the device fabrication process, which typically includes a high-temperature annealing step. Accordingly, researchers applied proton implantation at different doses on 4H-SiC wafers and used them to fabricate PiN diodes. They then analysed the current-voltage characteristics of these diodes and compared them to those of a regular diode without proton implantation. Finally, they captured electroluminescence images of the diodes to check whether the stacking faults had formed or not.

The results indicated that the diodes that had undergone proton implantation performed just as well as regular ones, without signs of bipolar degradation. The deterioration of the current-voltage characteristics of the diodes caused by proton implantation at lower doses were not significant. However, the suppression of the expansion of single Shockley stacking faults was significant. The researchers hope these findings will help realise more reliable and cost-effective SiC devices that can reduce power consumption in trains and vehicles.

“Although the additional fabrication costs of proton implantation should be considered, they would be similar to those incurred in aluminium-ion implantation, currently an essential step in the fabrication of 4H-SiC power devices. Moreover, with further optimisation of implantation conditions, there is a possibility of applying this method for the fabrication of other kinds of devices based on 4H-SiC,” Kato said.

Organic transistor 'limitation' improves stability

Researchers have shown that a longstanding organic transistor design limitation actually improves...

OLED circular polarisation is now electrically switchable

Researchers have discovered a way to control left- or right-handed polarised light via charge...

Nanoscale pixels to advance augmented reality eyewear

Physicists have developed extremely small pixels that can be used in compact AR glasses, using...