Making the right product choices for harsh environments

Electronic devices and systems located in harsh environments will always struggle to perform as required if they are not built with the appropriate components.

A comprehensive understanding of the challenges to be faced by a device is therefore required for effective product sourcing and buying for harsh environments. There are many environmental dynamics to consider: these include the extremes of temperature, mechanical stresses such as pressure or vibration, prolonged exposure to chemicals such as fuel and gases, radiation and strong electromagnetic forces, or simply water, especially with its corrosive high-salinity content in marine applications.

Product selection

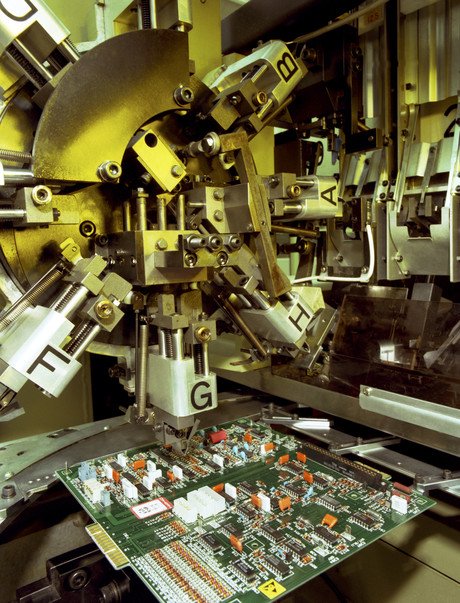

The range of electronic components designed for harsh conditions is wide and extends from radiation-hardened semiconductors to doubly pinned passives to conformal-coated connectors to electrically isolated power supplies among many others including switches, relays and fans. Fundamentally, and it is a message of paramount importance to buyers, there is usually a good reason why a particular part in the bill of materials has been selected by the designer.

A simple example is the design engineer’s selection of a bronze IP67-rated connector — protected against dust ingress and immersion in water — and its replacement with a cheaper aluminium device that also happens to meet IP67 but will not meet the demands of a saltwater environment. Another example is a power supply designed for use in an industrial automation application such as in a chemical- or food-processing plant. The product needs to be water-, ice-, oil- and dust-resistant, as well as being vibration- and shockproof, able to handle high temperatures and able to meet the appropriate rating for potentially explosive atmospheres.

Ratings

While IP ratings are reasonably well understood, perhaps less well known are the European ATEX ratings, which concern the control of explosive atmospheres and are very important in many industries including oil and gas, mining, power generation, food processing and manufacturing. ATEX ratings describe areas that contain flammable gases, mists and vapours or combustible dust; based on the level of risk, the ratings classify these areas that must be protected from sources of ignition into zones, classes and divisions. It is very important for buyers to know that ATEX ratings are not all the same and clearly understand the difference between zones to ensure effective product selection.

Materials

Materials are a key element in the selection of products and buyers need to be cautious when trying to make cost savings, as different materials offer very different properties. Major manufacturers such as TE Connectivity or Molex make standard interconnection product ranges in a wide variety of materials suitable for very diverse markets, as well as offering a wide range of mating cycles for heavy-duty applications. In addition, more bespoke interconnection products for highly specific harsh environments are available from manufacturers such as Amphenol, Bulgin, Harting and Hirschmann. Consequently, it is worth considering using a distributor with broad range of suppliers and expertise in harsh environments, especially when purchasing relatively small quantities of a part.

Overall, a thorough understanding of target conditions is important to make the right product choice, but even so, this will be a compromise between several competing requirements. For example, aluminium is a lightweight and electrically conductive metal that offers wide application use, but it is vulnerable to saltwater. Plastic is much less vulnerable and is also lightweight, but it is not electrically conductive and can be vulnerable to UV radiation. If very high tensile strength is required, then both of these materials would be a poor choice compared to stainless steel, but this would have a considerable impact on weight. In addition, materials can be vulnerable in environments that might appear safe at first glance; for example, highly acidic fluids and aggressive chemicals are present in the common domestic environment in the form of orange juice and cleaning fluids.

Helping with complexity

Overall, the selection of products for harsh environments can be a complex process — looking at attributes, materials or ratings in isolation provides just part of the picture. RS Components understands this well from its long experience in delivering components to a diverse range of businesses, in conjunction with a broad product range that will meet the demands of virtually all applications including some of the most specialist markets. Distributors such as RS can deliver a helpful and holistic service in selecting the right product for specific environments.

Turning peanut waste into graphene for next-gen electronics

UNSW Sydney engineers have developed a cheaper and greener way to make graphene from leftover...

Light-powered optical modules boost AI efficiency

Researchers have developed a new generation of AI hardware that runs on light instead of...

New materials could boost the energy efficiency of microelectronics

By stacking multiple active components based on new materials on the back end of a computer chip,...