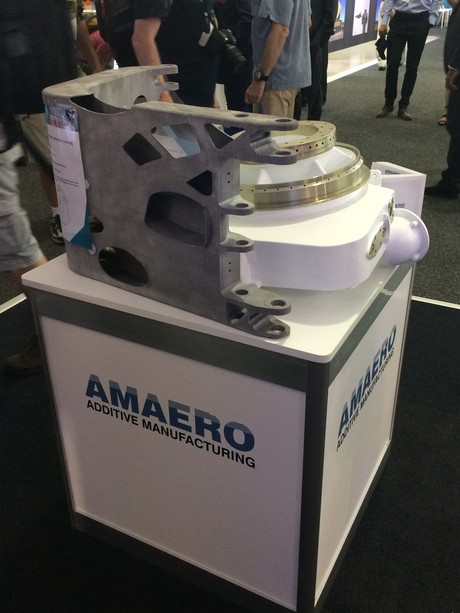

3D-printed aerospace components on show

Monash University has commissioned a $3.5 million Xline 2000R 3D printer — the world’s largest metal printer and one of only five made to date by German manufacturer Concept Laser.

The printer utilises the powder bed method of 3D printing, which uses a laser moving across a base plate to fuse fine coatings of metal powder, one layer at a time, to gradually build an object. It is the only one outside America and Europe, the only one based in a university and the only one in the Southern Hemisphere available for contract manufacturing.

“The new printer allows us to make large complex shapes and unique tools quicker, lighter and with less waste,” said Professor Xinhua Wu, who leads the Monash 3D printing initiative.

In 2015, Monash University and spin-off company Amaero Engineering presented the world’s first printed jet engine at Airshow 2015. In 2016, they printed components that are now flying in passenger jets and small turbojet engines. Now the partners have gone one step further with the production of the largest powder bed 3D-printed metal aerospace component printed to date — an aluminium door hinge from a Chinese jet airliner, measuring 40 x 80 x 39 cm in size and weighing an impressive 11 kg.

“We can literally go bigger,” said Amaero CEO Barrie Finnin. “This new capability will be of great interest to our aerospace and automotive customers in Europe, North America, Asia and Australia.”

The Amaero team will be presenting a range of printed components for inspection on their stand at Airshow 2017, including the first 3D-printed jet engine, the large jetliner door hinge, a large and complex air intake component and a cutaway view of a new rocket motor design. The show is being held at Avalon Airport from 3–5 March.

Nano framework unlocks printable 2D electronics

Researchers have developed a predictive framework for 2D-material exfoliation — enabling...

Light-based chip boosts AI power efficiency

Researchers have developed an optoelectronic silicon chip to perform convolution operations for...

Shining a UV light on next-gen computer chips

A recent study could help scientists and engineers build faster, cheaper and more eco-friendly...