Silicon can harvest energy from heat

A physicist from The University of Texas at Dallas has teamed with semiconductor company Texas Instruments to design a better way for electronics to convert waste heat into re-usable energy, demonstrating that silicon’s ability to harvest energy from heat can be greatly increased while remaining mass-producible.

Published in the journal Nature Electronics, the findings could greatly influence how circuits are cooled in electronics, as well as provide a method of powering the sensors used in the growing Internet of Things.

“Sensors go everywhere now — they can’t be constantly plugged in, so they must consume very little power,” said Dr Mark Lee, corresponding author on the study. “Without a reliable light source for photovoltaic energy, you’re left needing some kind of battery — one that shouldn’t have to be replaced.”

Dr Lee wanted to explore the concept of thermoelectric generation, whereby a difference in temperature is converted into electrical energy. He explained, “In a general sense, waste heat is everywhere: the heat your car engine generates, for example. That heat normally dissipates. If you have a steady temperature difference — even a small one — then you can harvest some heat into electricity to run your electronics.”

Sensors embedded beneath a traffic intersection provide an example of convenient thermoelectric power. Dr Lee explained, “The heat from tyres’ friction and from sunlight can be harvested because the material beneath the road is colder. So no-one has to dig that up to change a battery.”

The primary hurdles for widespread thermoelectric harvesting have been efficiency and cost, with Dr Lee noting, “Thermoelectric generation has been expensive, both in terms of cost per device and cost per watt of energy generated. The best materials are fairly exotic — they’re either rare or toxic — and they aren’t easily made compatible with basic semiconductor technology.”

Silicon, upon which so much technology relies, is the second-most abundant element in Earth’s crust. It has been known since the 1950s to be a poor thermoelectric material in its bulk, crystalline form. But in 2008, new research indicated that silicon performed much better as a nanowire — a filament-like shape with two of its three dimensions less than 100 nm. For comparison, a sheet of paper is about 100,000 nm thick.

“In the decade since those experiments, however, efforts to make a useful silicon thermoelectric generator haven’t succeeded,” Dr Lee said.

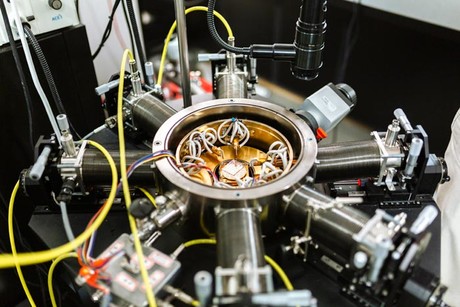

One barrier is that a silicon nanowire is too small to be compatible with chip-manufacturing processes. To overcome this, Dr Lee and his team relied on ‘nanoblades’ — only 80 nm thick but more than eight times that in width. While that is still much thinner than a sheet of paper, it’s compatible with chip-manufacturing rules.

Dr Lee acknowledged that the nanoblade shape loses some thermoelectric ability relative to the nanowire. “However, using many at once can generate about as much power as the best exotic materials, with the same area and temperature difference,” he said.

Study co-author Hal Edwards, a TI Fellow at Texas Instruments, designed and supervised fabrication of the prototype devices, with Dr Lee’s analysis having identified key metrics in which the low-cost silicon technology competes favourably with more exotic compound semiconductors. One key realisation was that some previous attempts failed because too much material was used.

“When you use too much silicon, the temperature differential that feeds the generation drops,” Dr Lee said. “Too much waste heat is used and, as that hot-to-cold margin drops, you can’t generate as much thermoelectric power.

“There is a sweet spot that, with our nanoblades, we’re much closer to finding than anyone else. The change in the form of silicon studied changed the game.”

Dr Lee said that the advanced silicon-processing technology at Texas Instruments allows for efficient, inexpensive manufacturing of a huge number of the devices.

“You can live with a 40% reduction in thermoelectric ability relative to exotic materials because your cost per watt generated plummets,” he said. “The marginal cost is a factor of 100 lower.”

Lead author Dr Gangyi Hu, who finished his doctorate in physics at UT Dallas in May, produced the computer modelling to determine the number of nanoblades per unit area that will produce the most energy without reducing the temperature difference. He revealed, “We optimised the configuration of our devices to place them among the most efficient thermoelectric generators in the world. Because it’s silicon, it remains low cost, easy to install, maintenance-free, long-lasting and potentially biodegradable.”

Dr Lee said the work was also novel because the team used an automated industrial manufacturing line to fabricate the silicon integrated-circuit thermoelectric generators.

“We want to integrate this technology with a microprocessor, with a sensor on the same chip, with an amplifier or radio, and so on,” he said. “Our work was done in the context of that full set of rules that govern everything that goes into mass-producing chips. Over at Texas Instruments, that’s the difference between a technology they can use and one they can’t.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Reviving Edison's nickel–iron battery for modern energy storage

Researchers have developed a nickel–iron battery technology, reviving a chemistry favoured...

Solid-state batteries: are we there yet?

Solid-state batteries could improve performance and safety in applications ranging from...

Battery chemistry used to break down forever chemicals

Scientists have found a new way to break down 'forever chemicals' — by borrowing...