Multilayered films shield solar cells from heat and moisture

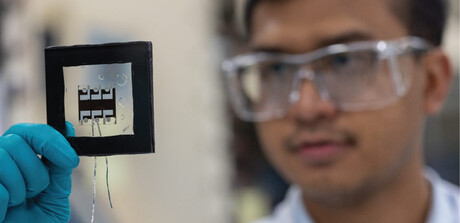

Researchers at the King Abdullah University of Science and Technology (KAUST) have developed multilayered perovskite-based films that shield high-performance perovskite solar cells from extreme heat and moisture, while also boosting their long-term stability. Their study has been published in the journal Science.

Perovskite solar cells have emerged as the fastest growing alternative to the conventional silicon technology that dominates the photovoltaic market. Cheaper and easier to manufacture, they have shown a dramatic continual rise in performance, potentially surpassing their silicon-based equivalents. However, inherent surface defects and ion migration affect the stability of the light-responsive perovskite film — a phenomenon that becomes more pronounced at higher temperatures.

Sandwiched between charge carrier-selective materials, the 3D perovskite film converts light to electricity by creating pairs of electrons and positively charged holes. Upon charge separation and collection, electrons migrate toward the ‘n-type’ layer while holes migrate toward the ‘p-type’ layer, producing an electric current.

2D perovskites are more resilient than their 3D counterparts under thermal stress and external conditions such as varying moisture and oxygen. Growing a 2D perovskite layer on top of a 3D perovskite film produces a heterojunction that blocks ion migration as well as moisture and oxygen. These 2D perovskite capping layers also considerably improve the resistance of unsealed devices against extreme outdoor-like moisture and thermal stress.

While this top-contact passivation approach has enhanced the performance and stability of regular solar cells, in which the p-type layer is at the top, so far it has failed for inverted devices, where the n-type layer is at the top. Randi Azmi, lead author on the new study, noted, “External conditions are not an issue for a sealed device, but the intrinsic thermal instability of the perovskite film remains problematic.”

Taking this approach further, Azmi and colleagues discovered that tailoring the number of inorganic sheets, or dimensionality, of the 2D perovskite component was crucial for an effective top-contact passivation. The researchers generated heterojunctions containing 2D perovskites of varying dimensionalities at the n-type interface of inverted solar cells, then deposited the cation precursor oleylammonium iodide on the 3D film to grow the 2D layer in situ and allowed it to self-organise at room temperature overnight.

Heterojunctions involving 2D perovskites were shown to substantially increase the device performance and stability when they had a dimensionality of two. The devices delivered a power conversion efficiency of 24.3% and retained more than 95% of their initial value after more than 1000 hours under accelerated high-humidity, high-temperature test conditions, meeting a critical industrial stability standard for photovoltaic modules.

“The team is now designing new molecules for 2D perovskites to develop ultrastable inverted perovskite solar cells with efficiencies close to those of regular devices that exceed 25%,” Azmi said.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Molecular Velcro coating boosts solar cell efficiency

Researchers have developed a new coating layer that enhances the durability and efficiency of...

Predictive AI model enhances solid-state battery design

ECU researchers are working on ways to make solid-state batteries more reliable with the help of...

Boosting performance of aqueous zinc–iodine batteries

Engineers from the University of Adelaide have enhanced aqueous zinc–iodine batteries using...