Choosing the right surface finish for your PCB

Printed circuit boards (PCBs) are essential components in the manufacturing of electronic devices ranging from smartphones and industrial machines to specialised aeronautic systems. While designers often focus on the circuit layout and picking the right parts, one key detail that doesn’t get enough attention is the surface finish on the PCB. This thin coating can make a big difference in how well the board performs, how long it lasts and how reliable it is.

There are plenty of surface finishes to choose from for PCBs, each designed for different conditions, budgets and compatibility needs. This article analyses PCB surface finishes: their types and how to select an appropriate surface finish for various PCBs.

Understanding PCB surface finish

It is important to know what a surface finish actually is and why it matters. Surface finishes are the thin layer of coating that’s applied to copper surfaces on a PCB. Without it, the copper would be exposed to the elements, which would quickly lead to oxidation and corrosion. And this, of course, means the PCB would soon develop catastrophic faults. This finish serves several crucial functions:

Protection: It shields the copper from oxidation and corrosion, ensuring the board’s longevity.

Solderability: It provides a surface suitable for soldering components.

Conductivity: It maintains good electrical conductivity for component connections.

Aesthetics: It can enhance the visual appeal of the PCB.

Picking the right finish affects all these things, so it’s a decision worth getting right during manufacturing.

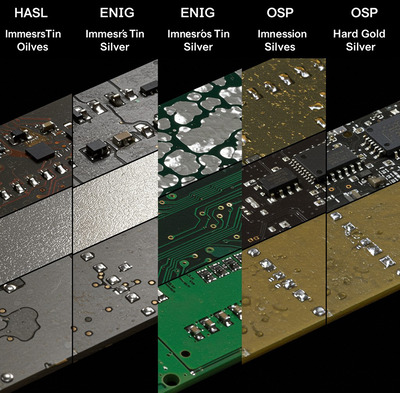

Let’s explore some of the most popular PCB surface finish options available in the market:

1. Hot air solder levelling (HASL)

HASL is a type of finish used on PCBs. The PCB is typically dipped into a bath of molten solder so that all exposed copper surfaces are covered by solder. Excess solder is removed by passing the PCB between hot air knives.

Advantages:

- Excellent solderability: the solder coating improves the ability of components to be soldered to the board.

- HASL-coated boards have a longer shelf life compared to other finishes like OSP.

- HASL is a relatively inexpensive and readily available surface finish.

- It provides a consistent and even layer of solder, promoting reliable solder joints.

Disadvantages:

- Not ideal for fine-pitch components. The unevenness of the HASL finish can be a problem for fine-pitch surface mount technology (SMT) components, making it unsuitable for certain applications.

- Traditional HASL uses a tin–lead alloy, which can be a concern for environmental regulations. Lead-free HASL options are available.

- Thermal stress: the heat involved in the HASL process can potentially stress the PCB laminate.

- Not suitable for high-frequency applications.

- Not suitable for PTH (Plated Through Hole) components.

2. Electroless nickel immersion gold (ENIG)

Electroless nickel immersion gold (ENIG) is a type of surface plating used for PCBs. It consists of an electroless nickel plating covered with a thin layer of immersion gold, which protects the nickel from oxidation.

This combination provides corrosion resistance, solderability and good electrical properties. ENIG is commonly used to protect copper pads and plated through-holes from oxidation and to facilitate soldering.

Advantages:

- The primary benefits of ENIG are its excellent surface planarity. This makes it particularly suitable for PCBs with fine-pitch components.

- Robust barrier against oxidation: the nickel layer acts as a barrier to prevent copper from the PCB from oxidising, while the thin layer of gold protects the nickel from oxidation.

- Good for high-frequency applications.

- ENIG is an excellent surface finish for wire bonding applications because it provides a highly conductive surface that is easy to bond to.

- ENIG is suitable for multiple reflow cycles, making it a good choice for applications that require repeated assembly.

- Long shelf life, more than one year in controlled conditions.

Disadvantages:

- One of the primary drawbacks of ENIG is its higher cost than other surface finishes, such as HASL or OSP (organic solderability preservative). The ENIG process involves the deposition of both nickel and gold layers, which contributes to the increased cost.

- Another challenge with ENIG is the potential for ‘black pad’ syndrome, a defect that can occur during electroless nickel deposition. This defect is characterised by a brittle, non-uniform nickel layer, which can lead to poor solder joint reliability and potential failure of the PCB.

- ENIG is susceptible to thermal shock, which can cause the nickel layer to crack and peel. This can lead to poor adhesion and other problems.

- Not good for rework and makes PCB repair difficult.

- Less suitable for high-current applications.

3. Immersion tin

Immersion Tin (ISn) is a metallic finish deposited by a chemical displacement reaction that is applied directly over the basis metal of the circuit board, ie, copper. The ISn protects the underlying copper from oxidation over its intended shelf life. It’s a more affordable option than ENIG and immersion silver, and it is also RoHS-compliant. A typical thickness for immersion tin is 20–50 µ″. Due to the way tin and copper interact, they eventually diffuse into one another.

Advantages:

- Good solderability: the tin finish readily wets and solders just like bare copper, unlike HASL or ENIG.

- Flat surface suitable for fine-pitch components.

- More affordable than electroless nickel-immersion gold.

- Preferable for press fit pin insertion.

Disadvantages:

- Shorter shelf life than ENIG due to tin whisker growth.

- Potential for copper dissolution during the plating process.

- Not ideal for multiple reflow cycles/assembly processes.

- Can lead to tin whiskers.

4. Immersion silver

Immersion silver (IAg) is applied directly to the base metal of a PCB via chemical displacement. It’s a more affordable option than ENIG, and it is also RoHS-compliant. A typical thickness for immersion silver is 4–12 µ″. Due to the way copper and silver interact, they eventually diffuse into one another.

Advantages:

- Excellent solderability.

- Good for high-frequency applications.

- Less expensive than immersion gold.

- Flat surface suitable for fine-pitch components.

Disadvantages:

- Prone to oxidation and tarnishing.

- Requires careful handling and storage.

- Higher cost compared to HASL.

- Very short shelf life: immersion silver on PCBs typically has a shelf life of six to 12 months under dry storage conditions. After this period, solderability may become a concern.

- When left unprotected from environmental influences, silver reacts with sulfur compounds, like those found in air, to form a black coating of silver sulfide (Ag2S). This reaction is what causes silver to tarnish or become dull. This phenomenon is known as corrosion, and specifically for silver, it’s called tarnishing.

5. Organic solderability preservative (OSP)

Organic solderability preservative (OSP) is an organic, water-based compound. It offers a flat finish and has the advantage of being lead-free. As the name indicates, it is an organic coating applied to the copper traces of a PCB to protect them from oxidation and maintain solderability. The OSP finish contains an organic acid that reacts with the copper surface to form a protective layer only a few atoms thick. This prevents air from reaching the copper and oxidising it.

Advantages:

- Appropriate for fine-pitch and BGA PCBs, as compared with HASL, OSP has a small tolerance. Both OSP and ENIG are used for fine-pitch PCB assembly and BGA PCBs.

- Has good solderability: in reflow soldering, OSP is removed completely and the bare PCB pads are directly soldered with the SMD components. The soldering effect of OSP PCBs is good.

- Cheap surface finish: applying OSP at room temperature is easy. OSP is among the cheapest PCB surface finishes.

- Environmentally friendly: OSP is a lead-free finish and does not introduce toxic substances, making it environmentally friendly.

- Good for high-frequency applications.

- Allows good contact resistance for ICT testing.

- Probe pins do not damage soft OSP coating.

Disadvantages:

- Limited shelf life: the storage period of OSP PCBs is within three to six months.

- Not suitable for applications requiring multiple reflow cycles.

- Cannot be used for plated-through holes.

- Less robust than metal finishes.

6. Hard gold

A hard gold finish, also known as electrolytic hard gold, is an electroplated gold layer that is thicker and more durable than other finishes like ENIG. It is alloyed with metals such as nickel or cobalt to enhance hardness and wear resistance, making it suitable for high-contact areas that require long-lasting electrical connections.

Hard gold applications are extremely durable and enjoy a long shelf life. They’re commonly reserved for components that expect to get a substantial amount of use. Hard gold is not often used for soldering points, due to poor solderability. It is typically used for edge connectors, battery contacts, test boards and keyboard contacts, all of which require robust, high-wear connections for data transmission and electrical continuity.

Advantages:

- Extremely durable.

- Excellent for applications requiring multiple insertions (eg, edge connectors).

- Very good corrosion resistance.

- RoHS compliant.

- Gold is an excellent conductor, ensuring reliable electrical connections.

Disadvantages:

- The most expensive option.

- Overkill for many standard applications.

- Can cause solderability issues if not properly applied.

- Poor solderability performance: hard gold is not easily soldered, making it less suitable for applications requiring solderability.

- Hard gold is not recommended for plated through-holes (PTH).

7. ENEPIG

ENEPIG (electroless nickel, electroless palladium, immersion gold) is a type of PCB surface finish that involves a three-layer coating on the copper pads of a printed circuit board. It consists of a nickel base, followed by a palladium layer, and a top layer of gold, all applied through electroless chemical processes. It is a similar to ENIG, except it adds a palladium layer to the mix. The combination of gold and palladium offers a more cost-effective plating solution than pure gold and is more durable than other finishes.

Advantages:

- The palladium layer in ENEPIG enhances wire bonding capabilities more than ENIG, especially for gold and aluminium wire bonding.

- Multiple reflow soldering capability.

- ENEPIG provides excellent solderability.

- The combination of nickel, palladium and gold provides robust corrosion resistance, protecting the underlying copper from environmental factors such as humidity and chemical exposure. This feature is crucial for PCBs used in harsh environments.

- ENEPIG-coated PCBs have a long shelf life due to the corrosion resistance provided by the palladium and gold layers.

- Lead free and RoHS compliant.

Disadvantages:

- ENEPIG is generally more expensive than other surface finishes such as HASL and OSP.

- The ENEPIG process involves multiple steps and requires precise control of plating thickness and uniformity. This complexity can lead to higher production costs and longer lead times compared to simpler surface finishes.

8. EPIG/EPAG

EPIG (electroless palladium immersion gold) and EPAG (electroless palladium autocatalytic gold) are nickel-free PCB surface finishes designed to avoid signal loss from nickel layers, making them ideal for high-frequency RF applications. Both use a palladium base layer topped with gold, but differ in gold deposition methods: EPIG uses immersion gold, resulting in a thinner layer, while EPAG employs autocatalytic gold, allowing for a thicker gold coating. This thicker layer in EPAG supports more demanding uses like gold wire bonding and soldering, making it more versatile. Both finishes are particularly suited for markets requiring non-magnetic bonding such as military, aerospace and deep-sea RF applications.

EPIG followed by a thin layer of immersion gold:

Advantages:

- Nickel-free, which is beneficial for high-frequency applications.

- Suitable for fine-pitch designs and high-density interconnects (HDI) as it eliminates the nickel layer.

- Can be used for both soldering and wire bonding.

- High reliability and uniform thickness.

Disadvantages:

- The immersion gold layer may be thinner compared to autocatalytic gold.

EPAG followed by a thicker layer of autocatalytic gold:

Advantages:

- Offers a thicker gold layer compared to EPIG, which can be beneficial for applications requiring more robust connections.

- Suitable for wire bonding and soldering.

- Can be used in demanding applications like military, aerospace and deep-sea RF due to its non-magnetic properties.

Disadvantages:

- The autocatalytic gold process may be more complex and require careful control.

Key Differences:

- Gold thickness: EPAG typically has a thicker gold layer than EPIG.

- Process complexity: EPIG is generally simpler to implement than EPAG.

- Applications: EPAG is often preferred for applications requiring thicker gold layers and more robust connections, while EPIG is suitable for fine-pitch designs and high-frequency applications.

Factors to consider when selecting a PCB surface finish

Application requirements

The primary factor guiding the selection of a PCB surface finish should be the intended application of the PCB. For instance:

- High-frequency applications typically benefit from finishes such as ENIG or immersion silver.

- For boards that will undergo multiple reflow cycles, finishes like ENIG or (HASL) may be more suitable.

- In areas subjected to wear, such as edge connectors, a hard gold finish is advisable.

- EPIG without the nickel layer improves signal performance in high-frequency and RF PCB design.

- EPAG and ENEPIG is typically the best option for wire bonding due to its thickness and uniformity.

Component technology

The nature of the components utilised will impact your finish choice:

- Fine-pitch components require a flat surface, making ENIG, immersion tin or OSP ideal options.

- Smooth and durable surface finishes, such as gold or immersion tin, are generally preferred for press-fit connectors.

- Any surface finish is typically compatible with through-hole components.

- Bottom terminated components (BTC) such as BGA and QFN perform optimally with ENIG.

Environmental conditions

It is essential to consider the operational environment of your PCB:

- In high humidity conditions, more corrosion-resistant finishes like ENIG are advisable.

- For applications exposed to extreme temperatures, hard gold and ENIG prove to be the most suitable options due to their superior durability and conductivity.

- When exposure to chemicals or solvents is anticipated, finishes with high corrosion resistance, like ENIG and hard gold, are preferred. Immersion tin and OSP may not withstand harsh environments as effectively.

Production volume and cost

Your production volume and budget constraints play a significant role:

- For high-volume production, HASL or OSP might be more cost-effective.

- For prototypes or low-volume production, ENIG or immersion tin could be suitable despite higher per-unit costs.

Shelf-life requirements

For long-term storage of your PCBs, keep in mind the following considerations:

- For a PCB surface finish that offers a prolonged shelf life, both ENEPIG and hard gold are outstanding options.

- ENIG also provides an extended shelf life and is suitable for a variety of applications.

- Alternative choices include immersion silver and HASL.

- It is important to ensure that materials are stored in a humidity-free environment, following established guidelines to achieve optimal results.

- OSP and immersion finishes generally have shorter shelf lives, normally not longer than six months.

Regulatory compliance

It is important to keep in mind that different industries will have particular compliance requirements.

- PCB surface finish choices can significantly impact regulatory compliance, primarily concerning RoHS directives and other environmental standards. The type of finish, like HASL, ENIG or OSP, determines its ability to comply with restrictions on heavy metals and other substances. Some finishes, particularly those involving lead, may not be compliant, requiring alternative options.

- As other examples, medical or aerospace applications might have certain finishing requirements. Make sure the finish is appropriate per industry standards such as IPC and military specifications like MIL-PRF-50884 for aerospace.

Conclusion

Selecting the right surface finish for your PCB is a crucial decision that can significantly impact the product’s performance, reliability and cost. By understanding the characteristics of different finishes and carefully considering specific requirements, you can make an informed choice that optimises your PCB for its intended application.

Remember, there’s no one-size-fits-all solution when it comes to PCB surface finishes. Each project may require a different approach, and what works best for one application might not be ideal for another. Stay informed about new developments in surface finish technology, as innovations in this field continue to offer new possibilities for PCB design and manufacturing.

By taking the time to select the best surface finish for your PCB, you’re investing in the quality and longevity of your electronic products. Whether you’re working on a high-frequency communication device, a rugged industrial controller or a cutting-edge medical device, the right surface finish can make all the difference in achieving optimal performance and reliability.

What does cybersecurity look like in the quantum age?

As quantum computers are increasingly integrated into daily life, it will become critical to...

Transforming acoustic waves with a chip

Researchers have developed a chip that uses on-chip phased interdigital metamaterials to shape...

Mechanical strain boosts lead-free ferroelectrics

Scientists have discovered a way to boost the performance of lead-free ferroelectrics using pure...