Electrodes created with light

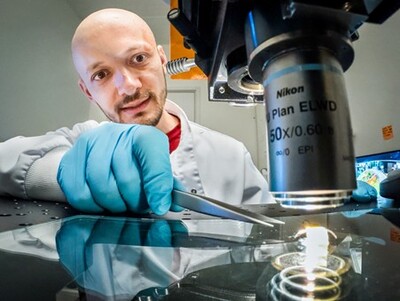

In a new study, researchers at Linköping and Lund Universities have shown that visible light can be used to create electrodes from conductive plastics, completely without hazardous chemicals. The electrodes can be created on different types of substrates, which opens up a new type of electronics and medical sensors.

“I think there is a bit of a breakthrough here. It is another way of creating electronics that is simpler and does not require any expensive equipment,” said Xenofon Strakosas, assistant senior lecturer at the Laboratory for Organic Electronics, LOE, at Linköping University.

At LOE, researchers are working with conductive plastics, also known as conjugated polymers, to develop new technologies in areas such as medicine and renewable energy. Conjugated polymers combine the electrical properties of metals and semiconductors with the flexibility of plastics.

Polymers are made up of long chains of hydrocarbons. Each individual link in the chain is called a monomer. When the monomers are linked together, polymers are formed. The process, called polymerisation, is often carried out using strong and sometimes toxic chemicals, which limits the possibility of scaling up the process and using the technology in areas such as medicine.

Tailor-made monomers

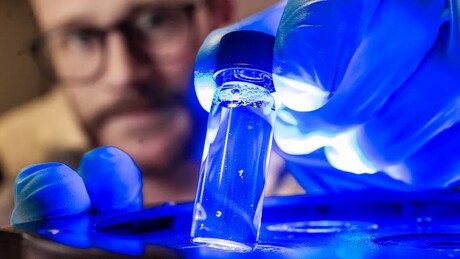

What the researchers at Campus Norrköping, together with colleagues in Lund and New Jersey, have now managed to create is a method where the polymerisation can take place only with the help of visible light. This is thanks to specially designed water-soluble monomers that the researchers have developed. This means that no toxic chemicals, harmful UV light or subsequent processes are needed to create the electrodes.

“It is possible to create electrodes on different substrates such as glass, textiles and even skin. This opens up a much broader spectrum of applications,” Strakosas said.

In practice, the solution with the monomers could be placed on a substrate. Using, for example, a laser or other light source, it is possible to create electrodes in intricate patterns directly on the substrate. The solution that has not polymerised can then be rinsed away, leaving the electrodes.

“The electrical properties of the material are at the absolute cutting edge. Thanks to the material’s ability to transport both electrons and ions, it can communicate with the body in a natural way, and the gentle chemistry means that tissues tolerate it — a combination that is crucial for medical applications,” said Tobias Abrahamsson, researcher at LOE and first author of the article published in the scientific journal Angewandte Chemie.

New type of sensors

The researchers have tested the technology by photopatterning electrodes directly onto the skin of anesthetised mice. The results show a clear improvement in recording low-frequency brain activity compared to traditional metal EEG electrodes.

“Since the method works on many different surfaces, one could also imagine sensors built into garments. In addition, the method could be used to manufacture organic electronic circuits on a larger scale without hazardous solvents,” Abrahamsson said.

Next-gen polymer IR lens technology for thermal imaging

Flinders University researchers have developed a sustainable, repairable and recyclable polymer...

Quantum-inspired wireless tech to boost 6G performance

Researchers have developed a quantum-inspired method for optical wireless communication, to...

Internal quantum batteries to power scalable quantum CPUs

A new quantum-battery‑powered architecture, developed by researchers from CSIRO and the...