Next-gen adhesive technology for micro-LED displays

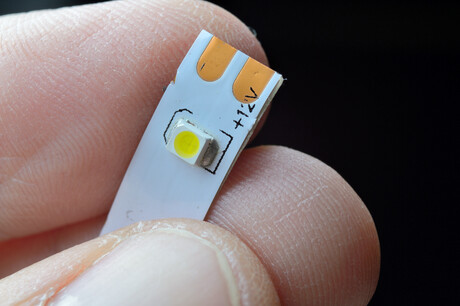

Researchers from Pohang University of Science and Technology (POSTECH) have developed a novel dry adhesive technology that allows everything from microscale electronic components to common household materials to be easily attached and detached. Micro-LEDs, a next-generation display technology, offer significant advantages such as higher brightness, longer lifespan and the ability to enable flexible and transparent displays. However, transferring micro-LED chips — thinner than a strand of hair — onto target substrates with high precision and minimal residue can be challenging.

Conventional methods that rely on liquid adhesives or specialised films often result in overly complex processes, poor alignment accuracy or residual contamination. Researchers have also struggled with the adhesion paradox — the theoretical prediction that surfaces should strongly adhere at the atomic level, contrasted by the real-world difficulty of achieving strong adhesion due to surface roughness that limits actual contact area.

The POSTECH researchers leveraged this paradox; their solution lies in the use of shape memory polymers (SMPs) featuring densely packed nanotips. At room temperature, the surface remains rough, exhibiting low adhesion. When heated and pressed, the surface smooths out and achieves stronger adhesion. Upon reheating, the surface returns to its original rough state, thereby reducing adhesion and enabling easy release.

This technology provides over 15 atmospheres of adhesion strength during bonding and near-zero force detachment through a self-release function. The difference in adhesion strength between the ‘on’ and ‘off’ states exceeds a factor of 1000. The researchers also demonstrated precise pick-and-place of micro-LED chips using a robotic system and confirmed stable adhesion even with materials such as paper and fabric.

“This innovation allows for the precise manipulation of delicate components without the need for sticky adhesives,” said Professor Seok Kim of POSTECH. “It holds significant potential for applications in display and semiconductor manufacturing, and could bring about transformative changes when integrated with smart manufacturing systems across various industries.”

The research findings have been published in the journal Nature Communications.

Quantum-inspired wireless tech to boost 6G performance

Researchers have developed a quantum-inspired method for optical wireless communication, to...

Internal quantum batteries to power scalable quantum CPUs

A new quantum-battery‑powered architecture, developed by researchers from CSIRO and the...

Porous gold metamaterial tunes electronic behaviour

By changing the physical structure of gold at the nanoscale, researchers can drastically change...