Next-gen polymer IR lens technology for thermal imaging

A high-performance lens for infrared cameras invented by Flinders University researchers is emerging as a lower-cost, more sustainable option for industries that use thermal imaging cameras, including security and surveillance, medicine, electrical engineering, electronics, defence and autonomous vehicle operation.

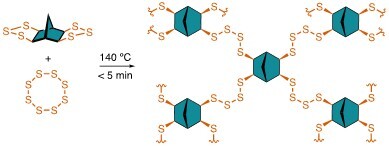

The new infrared thermal imaging lens, made from readily available and low-cost sulfur and other materials, replaces the need for traditional lenses which use expensive elements such as silicon and difficult-to-source germanium, according to new research published in the journal Nature Communications.

Thermal imaging cameras, which detect infrared light emitted from hot objects, are expanding in many practical applications and advanced technologies — from fire detection and wildlife monitoring and driver-assist or self-driving features in cars to energy-saving smart appliances.

“As demand for thermal imaging in consumer products rises, there is an increasing need for lower-cost optics. Our polymer lens provides a more sustainable alternative to more expensive inorganic materials such as germanium, silicon or chalcogenide glass,” said senior author and project director Professor Justin Chalker, from Flinders University’s College of Science and Engineering.

This new polymer can be moulded like a plastic — a critical capability for mass production — and made from abundant and low-cost elemental sulfur, and an organic co-monomer material. Millions of tonnes of surplus sulfur are produced every year, and the goal is to convert this abundant by-product from petroleum refining into value-added materials and sustainable technologies, Chalker said.

“The raw materials used to make this lens can cost less than 1 cent per unit, so it represents an extremely cost-effective, competitive alternative for the thermal camera and sensor market,” Chalker said.

First author Dr Samuel Tonkin added that the latest advances of the new lens will expand its appeal and use in consumer products such as smartphone IR cameras, fire detectors, driver-assist technology to detect pedestrians and animals at night, and energy-saving air-conditioners which increasingly rely on thermal imaging.

“As the prevalence of thermal imaging in consumer products increases, there is increasing demand for lower-cost optics. This pioneering Flinders technology addresses the challenges by being low cost, sustainable, repairable and recyclable,” said Tonkin, a Flinders University PhD graduate from the Chalker Lab.

“They can be made relatively quickly compared to the more expensive materials, such as germanium, which take time to run through milling processes and cannot be repaired if damaged,” Tonkin added.

The research team is working with collaborators at NASA to guide its use in imaging applications relevant to planetary science.

Quantum-inspired wireless tech to boost 6G performance

Researchers have developed a quantum-inspired method for optical wireless communication, to...

Internal quantum batteries to power scalable quantum CPUs

A new quantum-battery‑powered architecture, developed by researchers from CSIRO and the...

Porous gold metamaterial tunes electronic behaviour

By changing the physical structure of gold at the nanoscale, researchers can drastically change...