Novel network cuts latency and energy in smart factories

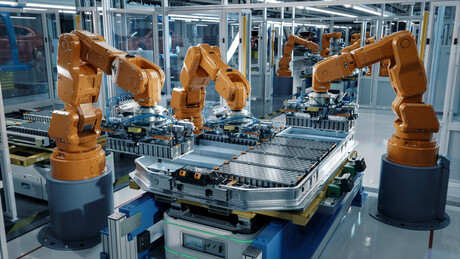

As manufacturers race towards smarter, faster and more automated production, the networks holding those systems together are coming under growing strain. Robots, sensors and autonomous machines all require split-second responses and iron-clad security — yet traditional 5G alone is not always built for the scale, cost and complexity of modern industrial environments.

New research from the University of East London (UEL) points to a potential way forward. A study led by Dr Athirah Mohd Ramly introduces PHWAN, a private hybrid wireless access network designed specifically for Industry 4.0 manufacturing, promising faster response times, lower energy use and stronger security for smart factories of the future.

Rather than relying on a single network technology, PHWAN brings multiple wireless systems — including 5G, Wi-Fi and low-power industrial networks — under one intelligent control framework. The principle is straightforward: different machines have different needs, so the network should adapt dynamically instead of forcing everything through the same channel.

In practical terms, this allows time-critical robots to be prioritised for ultra-low-latency connections, while sensors and monitoring devices use more energy-efficient links. By shifting more data processing closer to the factory floor, the framework also reduces reliance on distant cloud systems, cutting delays and lowering the risk of disruption.

The research team modelled large-scale smart manufacturing environments and found that the proposed approach could halve network latency compared with conventional 5G set-ups, while reducing energy consumption by more than 60%. For factories running thousands of connected devices, those gains could translate into smoother operations, lower running costs and a reduced environmental footprint.

Security is another central theme. Industrial networks are increasingly attractive targets for cyber attacks, with downtime carrying serious financial consequences. PHWAN adopts a zero-trust model, continuously verifying devices and users rather than assuming anything inside the network is safe. Decentralised authentication and AI-driven monitoring are designed to limit how far any breach can spread.

Ramly said the work reflects a growing need to rethink industrial connectivity from the ground up.

“Smart factories depend on communications that are not just fast, but predictable and secure,” Ramly said. “By combining different wireless technologies and managing them intelligently, PHWAN shows how industrial networks can be better aligned with the real demands of modern manufacturing.”

Beyond technical performance, the research highlights a broader shift in how connectivity is viewed within industry. As production systems become more autonomous and data-driven, networking infrastructure is no longer just a background utility, but a critical enabler of resilience and competitiveness.

The study was developed at UEL and is published in the Egyptian Informatics Journal, an international journal from Elsevier focusing on advances in informatics and intelligent systems.

Generating electricity using durable piezo-active nylon

Researchers from RMIT University have generated electricity from compression using a flexible...

Next-gen polymer IR lens technology for thermal imaging

Flinders University researchers have developed a sustainable, repairable and recyclable polymer...

Quantum-inspired wireless tech to boost 6G performance

Researchers have developed a quantum-inspired method for optical wireless communication, to...