Wireless connectivity boosted for wearables

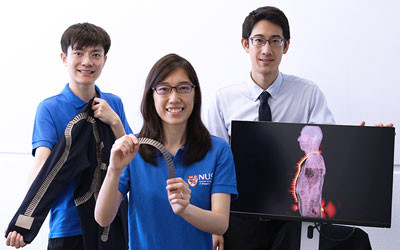

Researchers from the National University of Singapore (NUS) have invented a new way for wearable devices to interconnect, incorporating conductive textiles into clothing to dynamically connect several wearable devices at once.

Described in the journal Nature Electronics, this ‘wireless body sensor network’ is said to allow devices to transmit data with a 1000 times stronger signal than conventional technologies, meaning the battery life of all devices is improved. Wireless networks of these wearable devices on a body could have future applications in health monitoring, medical interventions and human–machine interfaces.

Over the past decade, a major trend in electronics has been the development of sensors, displays and smart devices which are seamlessly integrated onto the human body. Most of these wearable devices are singularly connected to a user’s smartphone and transmit all data via radio waves like Bluetooth and Wi-Fi. These waves radiate outwards in all directions, meaning that most of the energy is lost to the surrounding area. This method of connectivity thus reduces the efficiency of the wearable technology, as most of its battery life is consumed in attempting the connection.

Assistant Professor John Ho and his team from the Institute for Health Innovation & Technology (NUS iHealthtech) and NUS Engineering wanted to confine the signals between the sensors closer to the body to improve efficiency. Their solution was to enhance regular clothing with conductive textiles known as metamaterials.

Rather than sending waves into surrounding space, these metamaterials are able to create ‘surface waves’, which can glide wirelessly around the body on the clothes. This means that the energy of the signal between devices is held close to the body rather than spread in all directions. Hence, the wearable electronics use much less power than normal, and the devices can detect much weaker signals.

“This innovation allows for the perfect transmission of data between devices at power levels that are 1000 times reduced,” said Asst Prof Ho. “Or, alternatively, these metamaterial textiles could boost the received signal by 1000 times, which could give you dramatically higher data rates for the same power.”

In fact, the signal between devices is so strong that it is possible to wirelessly transmit power from a smartphone to the device itself, opening the door for battery-free wearable devices. Crucially, this signal boost does not require any changes to either the smartphone or the Bluetooth device — the metamaterial works with any existing wireless device in the designed frequency band.

This inventive way of networking devices is also said to provide more privacy than conventional methods. Currently, radio waves transmit signals several metres outwards from the person wearing the device, meaning that personal and sensitive information could be vulnerable to potential eavesdroppers. By confining the wireless communication signal to within 10 cm of the body, Asst Prof Ho and his team have created a network which should be more secure.

The metamaterial textile design consists of a comb-shaped strip of metamaterial on top of the clothing with an unpatterned conductor layer underneath. These strips can then be arranged on clothing in any pattern necessary to connect all areas of the body. The metamaterial itself is said to be cost-effective, in the range of a few dollars per metre, and can be bought readily in rolls.

“We started with a specific metamaterial that was both flat and could support surface waves,” Asst Prof Ho said. “We had to redesign the structure so that it could work at the frequencies used for Bluetooth and Wi-Fi, perform well even when close to the human body and could be mass produced by cutting sheets of conductive textile.”

The team’s particular design was created with the aid of a computer model to ensure successful communication in the radiofrequency range and to optimise overall efficacy. The smart clothing is then fabricated by laser-cutting the conductive metamaterial and attaching the strips with fabric adhesive.

Once made, the ‘smart’ clothes are highly robust. They can be folded and bent with minimal loss to the signal strength, and the conductive strips can even be cut or torn, without inhibiting the wireless capabilities. The garments can also be washed, dried and ironed, just like normal clothing.

The team has a first-year provisional patent on the metamaterial textile design and is now talking to potential partners to commercialise this technology, with Asst Prof Ho hoping to test the ‘smart’ textiles as specialised athletic clothing and for hospital patients to monitor performances and health. Potential applications could range from measuring a patient’s vital signs without inhibiting their freedom of motion to adjusting the volume in an athlete’s wireless headphones with a single hand motion.

“We envision that endowing athletic wear, medical clothing and other apparel with such advanced electromagnetic capabilities can enhance our ability to perceive and interact with the world around us,” Asst Prof Ho said.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Avoiding EMC issues: simple tests you can do yourself

This is a brief overview of EMC compliance with some practical tips on not getting caught out.

Electric dump valves help oil and gas company reduce emissions

Oil and gas company Laramie Energy deployed ASCO zero-emissions electric dump valves to comply...

Australia's largest electronics expo returns to Sydney

Electronex, the annual electronics design and assembly expo, will return to Sydney on 19–20...