High-efficiency laser created for silicon chips

Transistors in computer chips work electrically, but data can be transmitted more quickly by using light. For this reason, researchers have long been looking for a way to integrate lasers directly in silicon chips.

Scientists from Germany’s Forschungszentrum Jülich, working with the French Centre de Nanosciences et de Nanotechnologies (C2N), STMicroelectronics and CEA-Leti, have now developed a compatible semiconductor laser made of germanium and tin, whose efficiency is comparable with conventional GaAs semiconductor lasers on Si. Their work has been described in the journal Nature Photonics.

Optical data transfer permits much higher data rates and ranges than current electronic processes while also using less energy. Computation and data centres, therefore, already default to optical fibre whenever cables exceed a length of about one metre. In future, optic solutions will be in demand for shorter and shorter distances due to increasing requirements, for example, board to board or chip to chip data transfer. This applies particularly to artificial intelligence (AI) systems where large data volumes must be transferred within a large network in order to train the chip and the algorithms.

“The most crucial missing component is a cheap laser, which is necessary to achieve high data rates,” said Prof Detlev Grützmacher, Director at Forschungszentrum Jülich’s Peter Grünberg Institute Semiconductor Nanoelectronics (PGI-9). “An electrically pumped laser compatible with the silicon-based CMOS technology would be ideal. Such a laser could then simply be shaped during the chip manufacturing process since the entire chip production is ultimately based on this technology.”

But there’s one problem: pure silicon is an ‘indirect semiconductor’, and therefore unsuitable as a laser material. Different materials are currently used for manufacturing lasers. Generally, III–V compound semiconductors are used instead.

“Their crystal lattice, however, has a completely different structure than that of silicon, which is a group IV element,” Prof Grützmacher said. “Laser components are currently manufactured externally and must be integrated subsequently, which makes the technology expensive.”

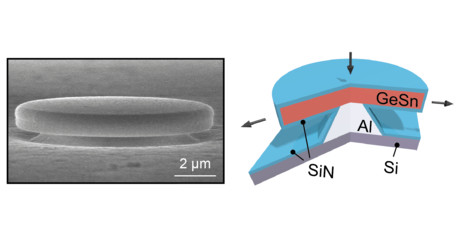

In contrast, the new laser can be manufactured during the CMOS production process. It is based on germanium and tin, two group IV elements like silicon. Back in 2015, Jülich researchers showed that laser emission can be obtained in a GeSn system. The decisive factor in this is the high tin content: back then, it amounted to 12%, which is far above the solubility limit of 1%.

“Pure germanium is, by its nature, an indirect semiconductor like silicon,” said Dr Dan Buca, working group leader at PGI-9. “The high concentration of tin is what turns it into a direct semiconductor for a laser source.”

The patented epitaxial growth process developed by Jülich is used by several research groups all over the world. By further increasing the tin concentration, lasers have already been made that work not only at low temperatures but also at 0°C.

“A high tin content, however, decreases the laser efficiency,” said PGI-9’s Nils von den Driesch. “The laser then requires a relatively high pumping power. At 12–14% tin, we already need 100–300 kW/cm2. We thus tried to reduce the concentration of tin and compensate this by additionally stressing the material, which considerably improves the optical properties.”

For the new laser, the researchers reduced the tin content to approximately 5% — and simultaneously decreased the necessary pumping power to 0.8 kW/cm2. This produces so little waste heat that this laser is the first group IV semiconductor laser that can be operated not only in a pulsed regime but also in a continuous working regime, ie, as a ‘continuous-wave laser’.

“These values demonstrate that a germanium–tin laser is technologically feasible and that its efficiency matches that of conventional III-V semiconductor lasers grown on Si,” Prof Grützmacher said. “This also brings [us] much closer to an electrical pumped laser for industrial-application that works at room temperature.”

The new laser is currently limited to optical excitation and low temperatures of about -140°C — but with improvements, it could be useful not only for optical data transfer but also for a variety of other applications, since there are hardly any cheap alternatives for the corresponding wavelengths in the infrared range of 2–4 µm. Potential applications range from infrared and night-vision systems all the way to gas sensors for monitoring the environment in climate research or even breath gases analyses for medical diagnosis.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

What does 'flexibility' actually look like?

Researchers have published a study that provides experimental evidence linking the mechanical...

Light reshapes semiconductors for advanced optical devices

Researchers have shown how light reshapes Janus semiconductors at the atomic scale, enabling...

Novel method to grow ultrathin semiconductors on electronics

Researchers have developed a technique that could speed up the development of next-generation...