World-leading thin-film solar cells are cheap, easy to make and non-toxic

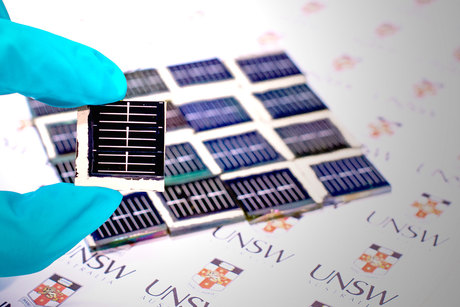

A UNSW research team has achieved the world’s highest efficiency for a full-sized thin-film solar cell using a competing thin-film technology known as CZTS. Led by Dr Xiaojing Hao of the Australian Centre for Advanced Photovoltaics, the researchers achieved 7.6% efficiency in a 1 cm2 area CZTS cell — a world-leading result which has been confirmed by the US National Renewable Energy Laboratory.

It is believed that the milestone will make it easier to achieve the dream of ‘zero energy’ buildings, which have until now been held back by two hurdles: the cost of the thin-film solar cells (used in facades, roofs and windows) and the fact that these solar cells are made from scarce, and highly toxic, materials.

Thin-film technologies such as CdTe (cadmium-telluride) and CIGS (copper-indium-gallium-selenide) are attractive options for the solar industry because they are physically flexible, which increases the number of potential applications. But cadmium and selenium are toxic at even tiny doses, while tellurium and indium are extremely rare. CZTS cells, on the other hand, are made from abundant materials — copper, zinc, tin and sulfur — and are non-toxic.

“In addition to its elements being more commonplace and environmentally benign, we’re interested in these higher bandgap CZTS cells for two reasons,” said Professor Martin Green, a mentor of Dr Hao.

“They can be deposited directly onto materials as thin layers that are 50 times thinner than a human hair, so there’s no need to manufacture silicon ‘wafer’ cells and interconnect them separately. They also respond better than silicon to blue wavelengths of light and can be stacked as a thin-film on top of silicon cells to ultimately improve the overall performance.”

By being able to deposit CZTS solar cells on various surfaces, Dr Hao’s team believe this puts them on the road to making thin-film photovoltaic cells that can be rigid or flexible, and durable and cheap enough to be widely integrated into buildings to generate electricity from the sunlight that strikes structures such as glazing, facades, roof tiles and windows. And because CZTS is cheaper — and easier to bring from lab to commercialisation — than other thin-film solar cells, applications are likely even sooner.

“This is the first step on CZTS’s road to beyond 20% efficiency and marks a milestone in its journey from the lab to commercial product,” said Dr Hao. In fact, UNSW is currently collaborating with a number of large companies keen to develop applications well before it reaches 20% efficiency — probably within the next few years.

“I’m quietly confident we can overcome the technical challenges to further boosting the efficiency of CZTS cells, because there are a lot of tricks we’ve learned over the past 30 years in boosting CdTe and CIGS and even silicon cells but which haven’t been applied to CZTS,” Dr Hao concluded.

Next-gen semiconductor material for light-based electronics

Scientists from the University of Edinburgh have created a new type of material that could enable...

Chip-scale optical amplifier enhances data and sensing

Energy-efficient and small enough to fit in a smartphone, an optical amplifier developed at...

Organic transistor 'limitation' improves stability

Researchers have shown that a longstanding organic transistor design limitation actually improves...