Manufacturing better, cheaper cathodes for Li-ion batteries

Researchers at the US Department of Energy’s Oak Ridge National Laboratory (ORNL) have developed a method to produce a key component of lithium-ion batteries, resulting in a more affordable battery from a faster, less wasteful process that uses less toxic material. Lithium-ion batteries — used in products from appliances to cell phones, as well as in most electric vehicles — are composed of a cathode and an anode with an electrolyte in between. Ions move from anode to cathode through the electrolyte in a reaction that converts chemical energy to electrical energy.

The drive toward decarbonisation and the demand for electric cars has increased the focus on sustainably producing energy-dense cathodes. However, traditional processing presents challenges. The first challenge is a dependence on cobalt, a rare metal mined and refined abroad. This dependence on foreign sources poses risks to American manufacturing supply chains and transportation infrastructure. Additionally, the balance of other metals common in cathodes can also make the manufacturing process longer and more hazardous. For example, high nickel concentration has led to the widespread use of a chemical-mixing method for cathode production that requires large quantities of ammonia for corrosive reactions. Using the toxic chemical increases costs, heightens health and environmental concerns, and wastes large amounts of water to reduce acidity.

ORNL researchers report in the Journal of Power Sources that they have developed a cleaner, cheaper, more efficient method for making a new class of high-capacity cathode material without cobalt. Instead of continuously stirring cathode materials with chemicals in a reactor, their hydrothermal synthesis approach crystallises the cathode using metals dissolved in ethanol. The ethanol is safer to store and handle than ammonia, and afterward it can be distilled and reused. ORNL’s Ilias Belharouak, the principal investigator for the project, said the process offers the advantage of moving the cathode industry to cleaner and more cost-competitive production while putting less burden on the environment.

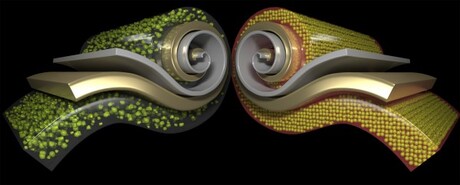

According to ORNL lead researcher Rachid Essehli, the hydrothermal synthesis method is also faster. The time required to make particles and prepare for the next cathode batch drops from as many as a few days to 12 hours. The material produced has more uniform, round, tightly packed particles that are ideal for a cathode, according to Essehli. Although the ORNL researchers have previously identified other cobalt-free combinations that work, the material developed through this study was better at maintaining stability throughout the battery charge cycle. Because its properties are similar to those of today’s cobalt-based cathodes, the new material can be integrated into existing battery manufacturing processes. A patent is pending on the technology, which is ready to be scaled up for commercial production by the industry. “This cathode material can give more energy and decrease the cost of electric car batteries,” Essehli said.

The research was funded by the US DOE Office of Energy Efficiency and Renewable Energy’s Vehicle Technologies Office. It used resources of ORNL’s Center for Nanophase Materials Sciences and the Advanced Photon Source at Argonne National Laboratory. Both are DOE office of Science user facilities.

Predictive AI model enhances solid-state battery design

ECU researchers are working on ways to make solid-state batteries more reliable with the help of...

Boosting performance of aqueous zinc–iodine batteries

Engineers from the University of Adelaide have enhanced aqueous zinc–iodine batteries using...

Sodium-ion battery breakthrough boosts energy storage

Scientists have discovered that leaving water inside a key material, rather than removing it,...