Simple algorithm predicts lithium battery failure

Researchers at the University of California San Diego have developed a simple yet powerful method to characterise lithium metal battery performance with the help of a widely used imaging tool: scanning electron microscopy. The advance could accelerate the development of safer, longer-lasting and more energy-dense batteries for electric vehicles and grid-scale energy storage.

Lithium metal batteries have the potential to store twice as much energy as today’s lithium-ion batteries. That could double the range of electric cars and extend the runtime of laptops and phones. But to realise this potential, researchers must tackle a longstanding challenge: controlling lithium morphology, or how lithium deposits on the electrodes during charging and discharging.

When lithium deposits more uniformly, the battery can achieve longer cycle lifetimes. By contrast, when lithium deposits unevenly, it forms needle-like structures known as dendrites that can pierce a battery’s separator and cause the battery to short-circuit and fail.

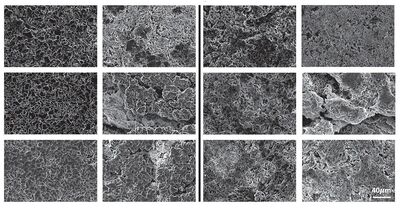

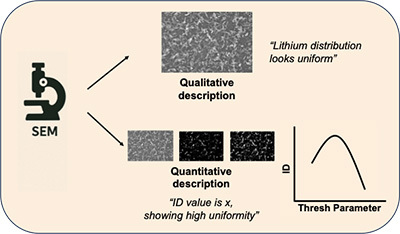

Historically, researchers have largely determined the uniformity of lithium deposits by visually assessing microscope images. This practice has led to inconsistent analyses between labs, which has made it difficult to compare results across studies.

“What one battery group may define as uniform might be different from another group’s definition,” said study first author Jenny Nicolas, a materials science and engineering PhD candidate at the UC San Diego Jacobs School of Engineering. “The battery literature also uses so many different qualitative words to describe lithium morphology — words like chunky, mossy, whisker-like and globular, for example. We saw a need to create a common language to define and measure lithium uniformity.”

To do so, Nicolas and colleagues developed a simple algorithm that analyses how evenly lithium is spread across scanning electron microscopy (SEM) images. The researchers used SEM because it offers detailed images of battery electrodes by capturing 3D surface features as 2D grayscale images — it is also a widely used technique in battery research.

To use their method, the team first takes SEM images of battery electrodes and converts them to black and white pixels. The white pixels represent the topmost lithium deposits in the sample and black pixels represent either the substrate or inactive lithium. The images are divided into multiple regions, and the algorithm counts the number of white pixels in each, then calculates a metric called the index of dispersion (ID).

“The index of dispersion is a measure of lithium uniformity,” Nicolas said. “The closer it is to zero, the more uniform the lithium deposits. A higher value means less uniformity and more clustering of lithium particles in certain areas.”

The team first validated the method on 2048 synthetic SEM images with known particle size distributions. The ID measurements aligned with the ground-truth distributions, which confirmed the method’s accuracy. The team then applied the method to real electrode images to analyse how lithium morphology changes over time under different cycling conditions. They found that as batteries cycled, the ID increased — indicating more uneven lithium deposits. Meanwhile, the energy required for lithium to deposit increased — a sign of degradation. In addition, the researchers found that local peaks and dips in the ID consistently appeared just before cells failed. Such peaks and dips could serve as an early warning sign of short circuits.

A big advantage of this method is that it is accessible. Battery researchers already use SEM imaging as part of their studies, Nicolas noted, and they can use the simple algorithm presented here to calculate the ID from the data they already collect.

“Our tool can be employed as a low-hanging fruit for researchers to take their analysis to the next level by utilising image analysis to its fullest potential,” Nicolas said.

The research findings were published in Proceedings of the National Academy of Sciences.

Reviving Edison's nickel–iron battery for modern energy storage

Researchers have developed a nickel–iron battery technology, reviving a chemistry favoured...

Solid-state batteries: are we there yet?

Solid-state batteries could improve performance and safety in applications ranging from...

Battery chemistry used to break down forever chemicals

Scientists have found a new way to break down 'forever chemicals' — by borrowing...