Solid-state batteries: are we there yet?

The modern world is increasingly dependent on reliable battery technology, from electric vehicles (EVs) and handheld devices to renewable energy storage. Improving performance while reducing battery weight and size is consequently a key focus across multiple industries.

There is a growing consensus that solid-state batteries will deliver the next technological step change. This relatively new type of battery is arguably lighter, safer and stronger than existing lithium-ion (Li-on) devices, and has a greater energy density.

Growth forecasts indicate a huge appetite for this new battery technology. In 2022, the global solid-state battery market was valued at $126.7 million. Its predicted valuation by 2030 is $1.646 billion. That’s a compound annual growth rate of almost 40% during the forecast period.1 One thing is certain: the solid-state battery market is set for significant growth, regardless of any technical challenges that must be overcome to scale up production.

The attraction of solid-state batteries

Part of the attraction of solid-state batteries lies in the shortcomings of existing rechargeable battery types. Although technologies such as Li-ion have advanced rapidly in recent years, they have inherent limitations that restrict the performance of many electronic devices.

Weight and capacity are two ongoing issues. In the automotive sector, these attributes can limit the range of an electric vehicle. In portable consumer devices, heavy batteries with limited capacity result in a bulkier design and frequent recharging. Safety is another area of concern. The liquid electrolyte that contains the lithium ions is highly volatile and flammable. It represents a potential fire or explosion risk, particularly when exposed to high temperatures or when the battery is overcharged.

The race is on to find alternatives to traditional liquid electrolyte cells that offer higher energy densities and enhanced safety measures. Assuming that technical hurdles can be overcome, solid-state batteries are the odds-on favourite because their underlying chemistry addresses many of the current weight, capacity and safety limitations inherent in traditional battery design.

How a solid-state battery works

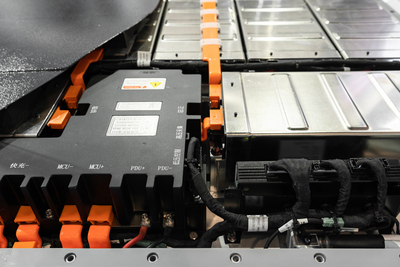

A typical Li-ion battery cell comprises two solid electrodes (the cathode and the anode), a central separator that acts as a mechanical barrier, and the liquid Li-ion electrolyte. By contrast, a solid-state battery consists of a solid ceramic or polymer substrate that serves as both separator and electrolyte. This arrangement effectively separates the cathode and the anode, which typically consists of pure lithium.

Solid-state batteries can use various types of solid electrolytes, each with unique properties. Ceramic electrolytes, for instance, offer high ionic conductivity and thermal stability, while sulfide electrolytes provide greater flexibility and improved ionic movement. Replacing flammable liquid electrolytes associated with Li-ion batteries with non-flammable solid electrolytes in solid-state batteries reduces risks such as thermal runaway and electrolyte leakage.

The different construction and pure lithium anode that characterise solid-state battery design help to achieve significantly enhanced energy densities. Solid-state batteries can potentially deliver energy densities as high as 11 kWh/kg, although a more realistic value in the short term is around 1 kWh/kg. In addition to surpassing the capabilities of current battery cells, solid-state technology could deliver a weight reduction of up to 30% for the same capacity.2

Potential applications for solid-state batteries

Superior weight-to-energy performance opens up many potential applications for solid-state batteries. One example is in automotive design, where increasing the battery pack energy density allows vehicle designers to reduce the total pack size, increasing the vehicle’s payload, or helping to boost its range. The advantages for the end-user — including improved energy efficiency, longer travel distances and fewer recharging stops — could be sufficient to convince more commercial vehicle operators and private car owners to switch from internal combustion engine-powered cars to EVs.

Many consumer electronics would also benefit from using solid-state batteries as an energy source. In addition to higher energy density, factors such as increased safety, longer lifespan and improved design flexibility are compelling reasons for incorporating solid-state technology into smartphones, laptops and wearables.

Looking further ahead, solid-state batteries could also speed up the development of smart cities. Digitisation relies on the widespread use of battery-powered Internet of Things (IoT) nodes, whether the application is manufacturing or urban development. IoT-based networks collect and analyse data to enable activities such as asset tracking, predictive maintenance, energy management and smart city monitoring. In this context, smaller, safer and longer-lasting batteries can improve performance and reduce the costs of IoT infrastructure, potentially accelerating the adoption of smart monitoring networks.

Removing barriers to adoption

The potential for solid-state batteries is abundantly clear, but the reality is that several technical and manufacturing challenges must be overcome before the technology is commercially viable. These include production complexities, scaling difficulties, material compatibility and longevity.

Broadly speaking, solid electrolytes have lower ionic conductivity than organic electrolytes, which limits the performance of solid-state batteries, particularly at room temperature. Solid-state batteries can also be relatively brittle, making them less durable.

Solid-state battery production requires the fabrication of thin, defect-free layers of solid electrolyte, plus the establishment of a very precise contact with the electrodes. These processes require highly accurate engineering and control. Scaling such processes presents quality and consistency challenges that must be overcome to achieve commercial viability.

Material selection and cost are further obstacles, according to a 2024 article titled Advancements and Challenges in Solid-State Battery Technology: An In-Depth Review of Solid Electrolytes and Anode Innovations. The authors highlight the difficulties in finding suitable materials for solid electrolytes with the required high ionic conductivity, mechanical strength and stability. Many promising solid electrolyte materials are costly or complex to synthesise in sufficient quantities, raising questions over the cost-effectiveness of solid-state batteries. Finding compatible electrode materials that can work efficiently with these solid electrolytes adds another layer of complexity.

Progress with solid-state battery commercialisation

Intensive research is being applied to overcome the materials and manufacturing challenges associated with solid-state battery production. In fact, several companies are close to producing commercially viable solid-state battery products, albeit at a relatively small scale.

TDK, for example, has introduced a proprietary material for its CeraCharge solid-state batteries. This next-generation technology offers an energy density of 1000 Wh/L, approximately 100 times greater than the energy density of the company’s early-stage solid-state batteries. According to TDK, this latest technology could replace existing coin cell batteries in wearable devices such as wireless earphones, hearing aids and smartwatches.3

Conclusion: On the brink of solid-state battery adoption

The excitement across multiple sectors surrounding the potential of solid-state batteries is justified. The technology holds enormous potential in EVs, consumer electronics and IoT networks, due to its inherent weight, safety, durability and energy density advantages, which significantly enhance performance. However, widespread adoption is still a little way off, as engineers grapple with the challenges of manufacturing, scalability and consistency.

Despite the challenges, continued advancements in nanotechnology, materials science and electrochemistry will likely help to overcome the barriers to adoption, paving the way for full commercialisation.

1. https://www.precedenceresearch.com/solid-state-battery-market

2. https://electronica.de/en/discover/industry-portal/detail/solid-state-battery-the-holy-grail-in-battery-research.html

3. https://www.tdk.com/en/news_center/press/20240617_01.html

Reviving Edison's nickel–iron battery for modern energy storage

Researchers have developed a nickel–iron battery technology, reviving a chemistry favoured...

Battery chemistry used to break down forever chemicals

Scientists have found a new way to break down 'forever chemicals' — by borrowing...

Amping up battery insights in the tropics

CSIRO researchers have collaborated with Malaysian authorities to examine how different battery...